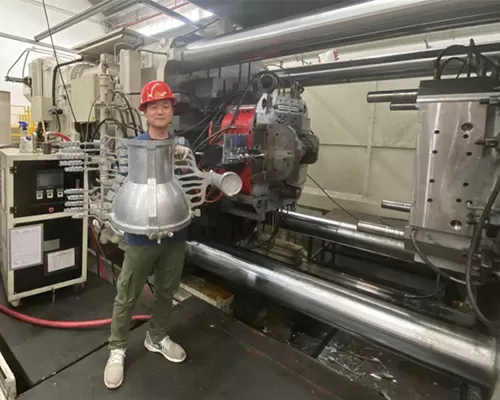

Wax pattern casting

Carbon steel castings have high strength and toughness, and can withstand large loads. They are commonly used in fields such as machinery manufacturing and construction.

Cast iron parts

Cast iron parts are widely used in many fields such as machinery manufacturing, automotive, construction, and metallurgy due to their characteristics like low cost, good casting performance, strong wear resistance, excellent shock absorption performance, and good machining performance.

Magnesium alloy

Magnesium alloy has the characteristics of low density, high specific strength and specific stiffness, good shock absorption performance, excellent electromagnetic shielding performance, and easy processing and forming.

Aluminum alloy

Aluminum alloy is widely popular in fields such as aerospace, automotive, electronics, machinery, construction, and daily necessities due to its advantages like light weight, corrosion resistance, high strength, and easy processability.

- Date

- 2024-11-05

- Date

- 2024-10-19

- Date

- 2024-11-05