What is rapid prototyping

Rapid prototyping technology can quickly transform early design concepts into physical models, thus providing a quick and cost-effective way to bring ideas to life. This method is particularly effective with technologies such as 3D printing, CNC machining, and can usually deliver a prototype within 1-3 working days.

The choice of prototyping is essential to speed up the design process and reduce the financial and operational risks associated with new product development. It enables the design to be thoroughly tested and refined, ensuring that each iteration is an improvement over the last. This process is critical to making informed decisions early in the development cycle, minimizing the risk of costly changes later in the development cycle.

Our Rapid Prototyping

Fast CNC prototyping services

CNC machining, including CNC milling and CNC turning, is an excellent choice for rapid prototyping as parts need to be evaluated in final material form. This approach allows prototyping with fully dense inventory, providing accurate and durable models. RapidDirect specializes in processing a wide range of metals and plastics, ensuring versatility to meet your project needs. Our fast CNC molding service delivers high quality machined prototypes quickly, usually within 1 day. This speed, combined with our affordable pricing, enables engineers to order multiple prototypes at once, facilitating rapid and thorough product evaluation.

Choosing RapidDirect for your CNC prototyping needs means you will benefit from our expertise and commitment to precision. We offer a variety of expeditable options to ensure urgent projects are completed on time. Our market-based pricing model ensures reasonable prices without compromising quality. With RapidDirect, you'll get detailed and accurate prototypes that support rapid product development, from initial design to final production.

Maximum part size:

CNC milling machine: 4000×1500×600 mm

CNC turning: 200×500 mm

Standard delivery time: 1 day

Tolerance: 0.001 inches

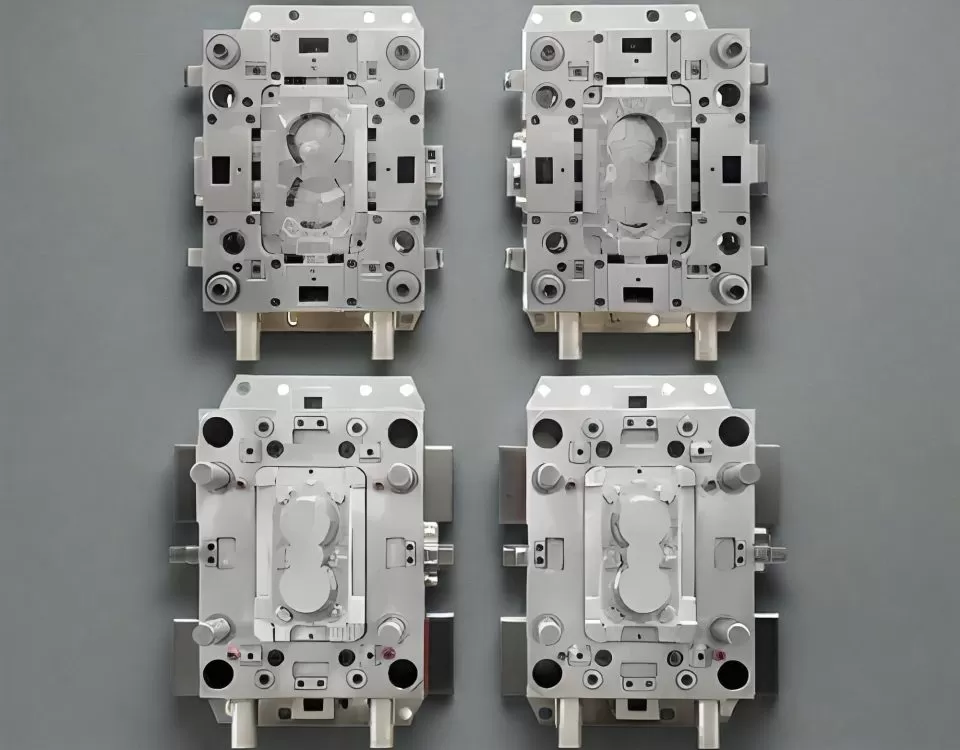

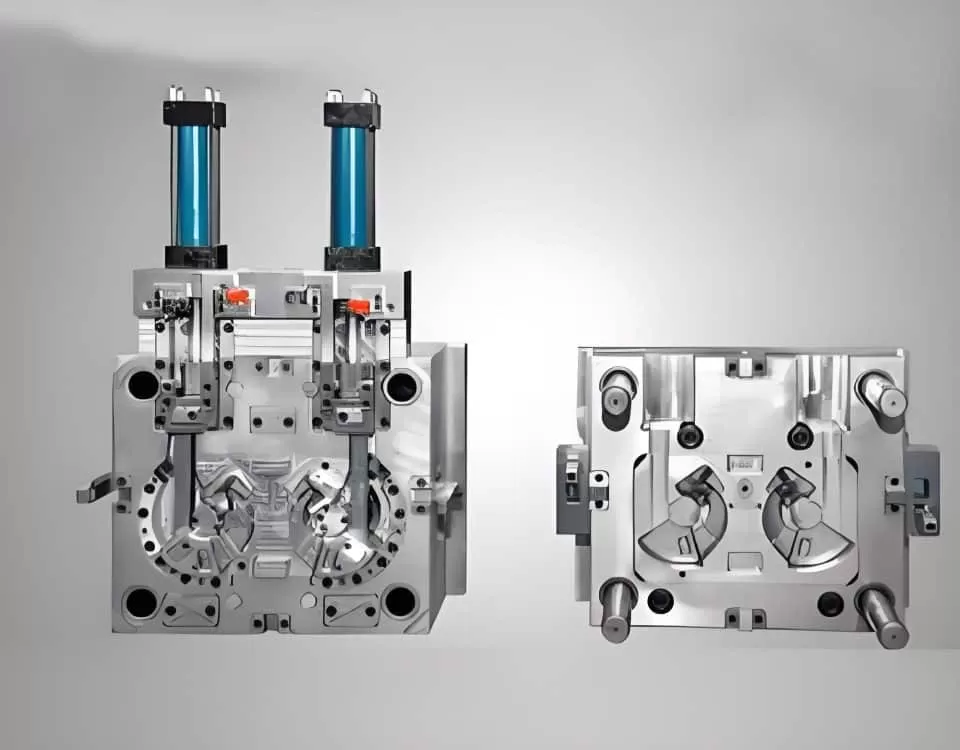

Rapid prototyping injection molding service

Injection molding is the first choice for prototyping when you need highly durable and consistent parts for extensive testing. This approach is ideal for high-fidelity product evaluation and for creating temporary bridging tools during product launches. Lead times for initial parts for rapid injection molding are typically 2-3 weeks, but with RapidDirect's expedited service, you can receive parts in as little as five days.

Choosing injection molding over 3D printing or CNC machining can be beneficial when your project requires strict material properties or specific mechanical requirements that cannot be achieved by other methods. RapidDirect excises in this regard, with each prototype being highly reproducible and close to the final shape. Our expertise ensures that you get reliable and accurate prototypes that contribute to effective product development and testing.

Maximum part size: ××1200, 1000, 500 mm

Standard delivery time: 2-3 weeks

Cavity tolerance: +/ -0.05mm

Rapid sheet metal forming service

Sheet metal processing is ideal for the production of flat parts that require rapid testing of the final metal form. This approach can produce prototypes in a week or less, providing fast and efficient solutions. It is also cost-effective and allows for the creation of multiple prototyping designs simultaneously. While aluminum 5052 is a common choice, we also offer a variety of other alloys, including steel, copper, and stainless steel.

Choosing RapidDirect for sheet metal prototyping ensures you benefit from our extensive experience and streamlined processes. We offer a wide range of materials and guarantee to provide high quality rapid metal prototyping services to meet your project requirements accurately and timely. With RapidDirect, you get reliable, accurate, and fast sheet metal prototype delivery, keeping your design process on time and within budget.

Cutting features: ±.00787 "(0.2 mm)

Bending Angle: ±1.0°

Bend to edge: +/-0.010 in (0.254 mm)

Bend to hole: +/- 0.2 mm

Standard delivery time: 1-2 working days

General tolerance: Metal: ISO 2768-c

Rapid 3D prototyping services

3D printing has emerged as a leading method for rapid prototyping due to its speed and cost-effectiveness. The technology enables rapid and cost-effective prototyping and is often ready for shipment within a day at minimal cost. The main 3D printing methods for rapid prototyping include selective laser sintering (SLS), stereo lithography (SLA), and melt deposition molding (FDM).

SLS is versatile, striking a balance between speed, mechanical functionality, fine resolution, and affordability. SLA offers the finest surface finish and excellent accuracy, making it ideal for manufacturing transparent parts with precise tolerances. FDM is well suited for the production of larger parts from a variety of engineering thermoplastics such as ABS, PC, and ULTEM, and is capable of fabricating items up to 36 inches in one go.

Choosing RapidDirect for your 3D printing needs ensures you benefit from our expertise and advanced features. We manufacture high quality 3D printed parts that meet your specific project requirements. With RapidDirect, you get reliable, accurate, and fast prototyping solutions that help accelerate your product development process.

To the maximum. Building size: 1400x700x500mm

Standard delivery time: 4-6 days

Dimensional tolerance: ±0.2mm(>100mm,Application 0.15%)

Rapid vacuum casting molding service

Vacuum casting is a preferred prototyping technique to produce high quality, fine replicas quickly and cost-effectively. This approach is especially advantageous when you need small to moderate quantities of functional plastic parts with injection-molded product quality. It can accurately replicate details and textures, making it ideal for test marketing, functional testing, and proof-of-concept demonstrations.

Choosing RapidDirect for vacuum casting means leveraging a streamlined process that ensures fast delivery and high fidelity for each prototype. Our rapid vacuum casting services offer a variety of materials and finishing options to meet a variety of prototyping needs. This flexibility, combined with our dedication to quality and speed, has made RapidDirect a leader in delivering prototypes that meet excruciating standards. With our expertise, you can accelerate your product development timeline while maintaining tight quality control.

Maximum part size: +/ -0.025m

Standard delivery time: up to 15 parts within 20 days

Tolerance: ±0.05 mm

How to choose the right rapid prototyping technology

Why Choose

Disadvantages

why did you choose us

Browse

Customer Cases

- Date

- 2024-10-15

- Date

- 2024-10-15

- Date

- 2024-10-15

GET IN TOUCH

What Is Rapid Prototyping?

Rapid prototyping means making a physical sample of a new product design idea. This is done as a preliminary step towards eventual production, and is most useful when verifying that the finished product will look, feel, and perform as intended. New product developers turn to rapid prototyping for several reasons. They’re used for functional testing, approvals, design iterations, for crowdfunding campaigns, trade show models, and as a bridge to low-volume manufacturing.

Prototypes often inspire re-designs, improvements, and other modifications that may not have been obvious merely from a computer graphic, so in this regard they’re beneficial for optimizing a design before committing resources to larger volumes. In fact, being able to correct design errors early in the development phase can more than compensate for the cost of the prototype itself, so they’re wise investments.

What Are The Different Types Of Rapid Prototyping?

Any physical model can potentially be a prototype. The difference lies in how closely it reflects the intended finished part.

Very simple models can be made with paper, plastic, modeling clay, styrofoam, balsa wood, or other common household materials. These are examples of very low-fidelity prototypes, but they do have the advantage of being easy and inexpensive to make.

These types of prototypes would likely not function very well or for long, so they’re used primarily to get a visual idea of the design and to compare it in scale to other parts.

More high-fidelity prototypes use modern machine tools and materials, including various 3D printing technologies, vacuum casting, rapid tooling for injection molding, and CNC machining.

Prototypes often inspire re-designs, improvements, and other modifications that may not have been obvious merely from a computer graphic, so in this regard they’re beneficial for optimizing a design before committing resources to larger volumes. In fact, being able to correct design errors early in the development phase can more than compensate for the cost of the prototype itself, so they’re wise investments.

How To Choose The Right Rapid Prototyping Technique

The right prototyping method is the one that best fits your budget, the complexity of the part, what you want the prototype to do, and your development timeline. Better prototypes cost more money and take longer to make, but they also more faithfully represent the form, fit, and function of a production part.

The basic questions to ask are these:

- Will the prototype be a static display model?

- Does it need to be fully functional?

- Are there multiple, interconnected parts?

- What is the surface texture and finish?

- What is it made from?

- How important is strength and durability?

- How closely should it match the final production version?

There are many variables to consider and we cannot cover them all here.