Drone weight reduction design

2025-08-05Custom aluminum chassis enclosures: manufacturing processes, material properties, applications, and advantages

Custom aluminum chassis enclosures are essential components across a wide range of industries, providing durable, lightweight, and efficient housings for electronic and mechanical systems. This article will delve into the manufacturing process, material properties, applications, and benefits of custom aluminum chassis enclosures.

What are the production methods of aluminum chassis shells?

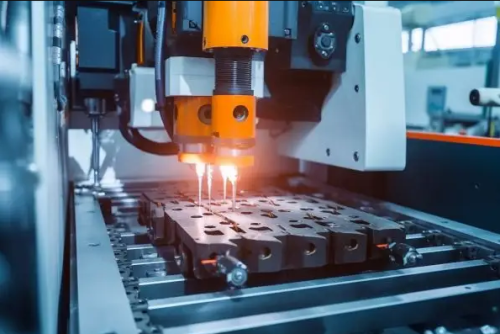

1. CNC processing

Computer numerical control (CNC) machines such as milling and turning are used to remove material from a solid block of aluminum to achieve the desired shape and size.

2. Die Casting

Molten aluminum is poured into a steel mold under high pressure and then cooled and solidified to form the part.

3. Sheet Metal Forming

Cut, bend, punch and weld aluminum sheets to form the desired housing shape.

4. Squeeze

The heated aluminum is extruded through a die to form long strips of uniform cross-sectional shape, which can then be cut and further processed as needed.

5. Casting

Molten aluminum is poured into a mold, allowed to cool and solidify, and then machined and finished.

6. Powder Metallurgy

Aluminum alloy powder is compressed into shape and then sintered at high temperatures to form dense, strong parts.

7. 3D Printing (Additive Manufacturing)

The parts are manufactured layer by layer using Selective Laser Melting (SLM) or Electron Beam Melting (EBM) technology.

The choice of custom aluminum chassis and enclosure manufacturing method depends on production volume, design complexity, cost considerations, and specific application requirements. CNC machining is ideal for high precision and custom designs, while die casting and sheet metal forming are suitable for high-volume production. 3D printing offers unparalleled design freedom and rapid prototyping capabilities. Selecting the most appropriate manufacturing process is crucial to ensuring product quality and cost-effectiveness. HXC has specialized in high-precision CNC machining of custom aluminum chassis and enclosures for over 20 years. The following article focuses on the CNC machining process, advantages, and applications of aluminum chassis and enclosures.

What are the custom CNC machining processes for aluminum chassis and cabinets?

1. CNC milling

Process: A rotating tool is used to remove material from the workpiece, creating complex shapes and fine details.

Advantages: High precision, suitable for complex geometries and tight tolerances.

2. CNC turning

Processing: The cutting tool removes material while the workpiece rotates, making this process suitable for machining cylindrical parts.

Advantages: High precision in machining circular parts and efficient production of symmetrical parts.

3. Drilling and tapping

Process: Drills and perforates holes for screws or bolts.

Benefits: Precise hole placement and consistency, critical for mounting components.

4. Multi-axis machining

Process: Uses CNC machines operating on multiple axes (e.g., three-, four-, or five-axis machines) to produce complex shapes in a single setup.

Advantages: Increases flexibility, reduces the need for multiple setups, and enables the machining of complex designs.

5. Electrical Discharge Machining (EDM)

Process: Utilizes electrical discharge to remove material, particularly suitable for difficult-to-machine shapes.

Advantages: High precision, capable of machining intricate details, and capable of machining complex geometries.

What are the advantages of CNC machining aluminum chassis cabinets?

Precision and accuracy

High Tolerance Levels: CNC machining allows for very tight tolerances, ensuring parts meet precise specifications.

Consistency: Provides high repeatability, ensuring every housing is exactly as designed.

Design flexibility

Complex Geometries: Capable of producing complex shapes and intricate designs that may not be possible with other manufacturing processes.

Customization: Easily accommodates design changes and custom features, making it ideal for prototyping and low-volume production.

Surface treatment

High-Quality Surface Finish: CNC machining produces a smooth surface finish that can be further enhanced through anodizing, polishing, or painting.

Post-Processing Options: A variety of surface treatments are available to enhance aesthetics and functionality.

Production efficiency

Reduced Waste: CNC machining optimizes material utilization and minimizes waste, which is both economical and environmentally friendly.

Recyclable: Aluminum scrap generated during machining can be recycled, enhancing the sustainability of the process.

Cost-effective processing of small and medium batches

Tooling costs: Initial tooling costs are low compared to processes like die casting or injection molding, making it cost-effective for small to medium-volume production.

Setup flexibility: Quick setup changes enable efficient switching between different designs or production batches.

Enhanced performance

EMI/RFI Shielding: Aluminum provides a natural shield against electromagnetic interference (EMI) and radio frequency interference (RFI), protecting sensitive electronic components.

Weight-to-Strength Ratio: Aluminum offers an excellent balance between weight and strength, making it suitable for applications where weight is a concern.

Prototyping and Iteration

Rapid Prototyping: CNC machining is ideal for rapid prototyping, enabling quick design iterations and testing.

Low-Volume Production: Efficiently handles low-volume production runs without extensive tooling or setup.

Versatility

Multi-Axis Machining: The capabilities of multi-axis CNC machines allow for complex and detailed machining of multiple sides of an enclosure in a single setup.

Various Functionalities: A variety of functions, such as threaded holes, mounting points, and complex internal geometries, can be integrated directly into the enclosure design.

What are the material properties of aluminum chassis?

Strength and Durability: Aluminum offers an excellent strength-to-weight ratio, making it both strong and lightweight.

Thermal Conductivity: Efficient heat dissipation is crucial for electronic chassis to prevent overheating.

Corrosion Resistance: Aluminum is naturally corrosion-resistant, and anodizing or coating can further enhance its corrosion resistance.

EMI/RFI Shielding: Aluminum effectively blocks electromagnetic and radio frequency interference.

Machinability:Aluminum is relatively easy to machine, reducing manufacturing time and costs.

What are the applications for aluminum enclosures?

1. Industrial Equipment

Enclosures for control panels, machinery enclosures, and automation systems.

2. Telecommunications

Enclosures for networking equipment, servers, and communications equipment.

3. Medical Equipment

Protective enclosures for medical devices and instruments.

4. Aerospace & Defense

Durable enclosures for avionics, radar systems, and military electronics.

5. Consumer Electronics

Custom enclosures for high-end audio equipment, gaming consoles, and home automation systems.

6. Automotive

Enclosures for automotive electronics, such as ECU housings and sensor covers.

7. Renewable Energy

Enclosures for solar inverters, battery storage systems, and wind turbine controllers.

8. Marine

Enclosures for navigation systems, communications equipment, and other marine electronics.

Summary

Custom aluminum enclosure machining leverages the precision and versatility of CNC technology to produce high-quality, durable, and precisely customized enclosures for a variety of applications. The material properties of aluminum combined with the advantages of CNC machining make it an excellent choice for industries demanding high performance, reliability, and customization. HXC offers high-quality, high-precision custom CNC machining services for aluminum enclosures.