Custom High-precision Injection Molding Components

Manufacturer

High precision injection parts customized manufacturers

HXC has more than 20 years of experience in mold manufacturing and injection molding industry.

We insist on the concept of customer-first, service-driven ,and continuously improve manufacturing service, focusing on customized processing of high-precision molds and providing precision injection molding product production services, including mold design, mold manufacturing, injection molding, surface treatment, product assembly and packaging one-stop OEM/ODM customized services.

Over the past 20 years, HXC has been verified by the market and has always insisted on technological innovation, we aim to provide high precision mold for more companies all over the vorld .

- We are committed to the research and development of injection mold solutions. By developing more efficient solutions and technologies that are closer to customer needs, we have cutting-edge technologies in two-color molding, three-color molding, gas-assisted applications, and high-gloss molding.

- At the same time, based on our outstanding production capabilities, we provide customers with electroplating products, high-gloss products, multi-color products, food and medical products, large products, and other precision products.

- From mold flow and DFM analysis to injection molding process, a team of engineers with rich experience provides strong support to make sure your project successful.

- We turn your ideas into accurate prototypes, accelerating product development through technologies such as 3D printing, CNC machining and injection molding. We help you to test and validate the parts fastly. So your design can smoothly go from concept to market. Using 3D printing, CNC machining and injection molding. Rapidly iterate and improve designs with high precision processing is our advantages. Ensure prototypes are exactly as you specify. Learn more.

-

R&D StrengthWith over 20 years of innovative ideas, HXC has been steadily growing. We have always adhered to the concept of building new products based on customer needs. Our flexible cross-functional teams, organized into project groups, execute new product development tasks. Adopting the IPD (Integrated Product Development) model, we collaborate as a team, putting customer needs at the center, prioritizing customer demands, development, and the fierce market competition, and integrating technology with customer perceptions within our execution team.

R&D StrengthWith over 20 years of innovative ideas, HXC has been steadily growing. We have always adhered to the concept of building new products based on customer needs. Our flexible cross-functional teams, organized into project groups, execute new product development tasks. Adopting the IPD (Integrated Product Development) model, we collaborate as a team, putting customer needs at the center, prioritizing customer demands, development, and the fierce market competition, and integrating technology with customer perceptions within our execution team. -

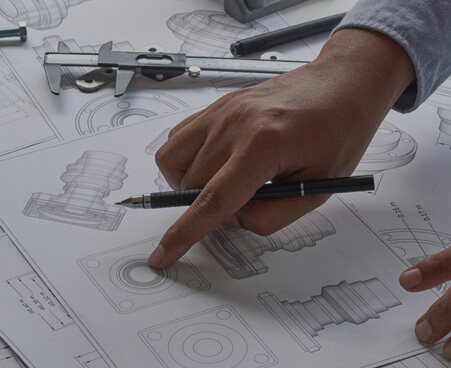

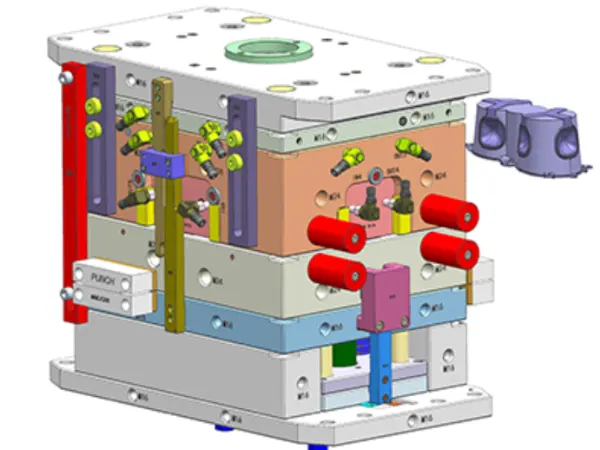

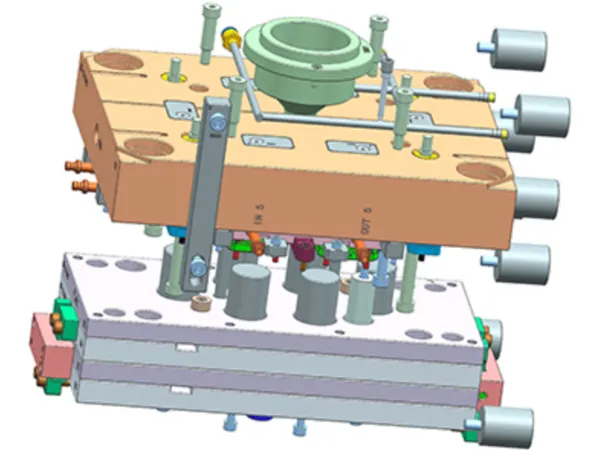

Design StrengthOur company boasts an engineering design team of over 35 members, including seasoned designers with over a decade of experience and high-level talents recognized by the city of Shenzhen. HXC has obtained more than 20 national patents, and after over 20 years of accumulation, we possess significant technical advantages in the industry.

Design StrengthOur company boasts an engineering design team of over 35 members, including seasoned designers with over a decade of experience and high-level talents recognized by the city of Shenzhen. HXC has obtained more than 20 national patents, and after over 20 years of accumulation, we possess significant technical advantages in the industry. -

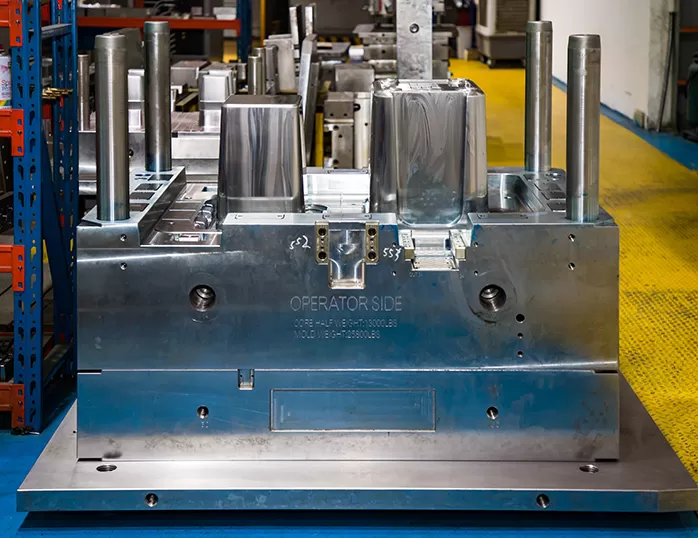

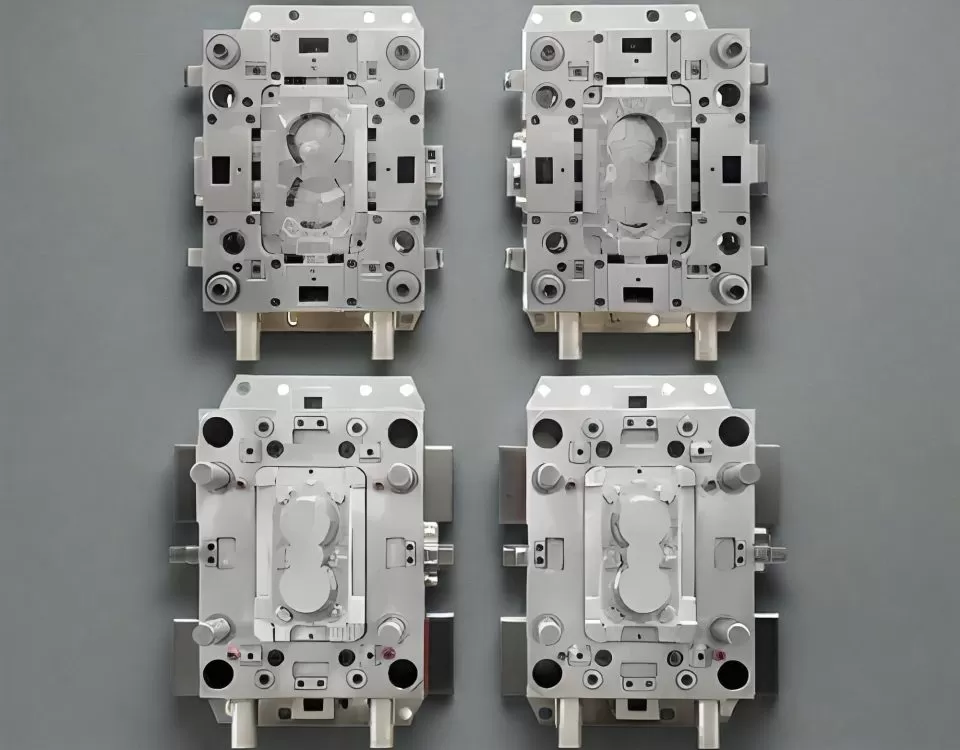

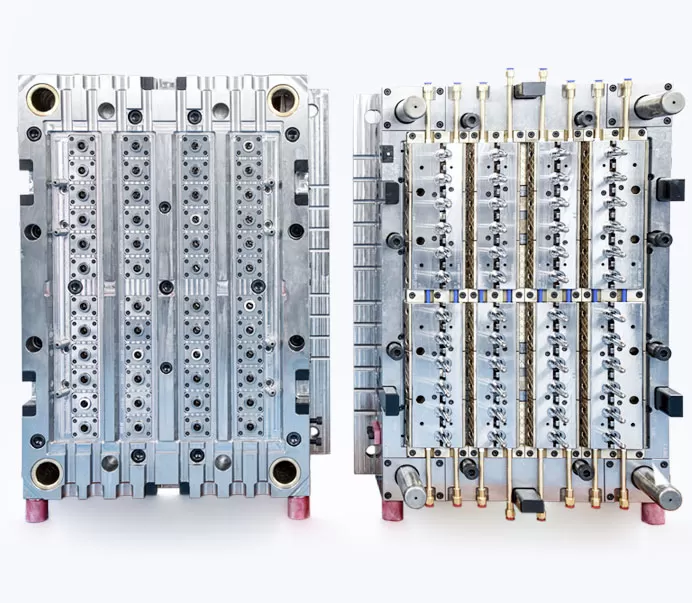

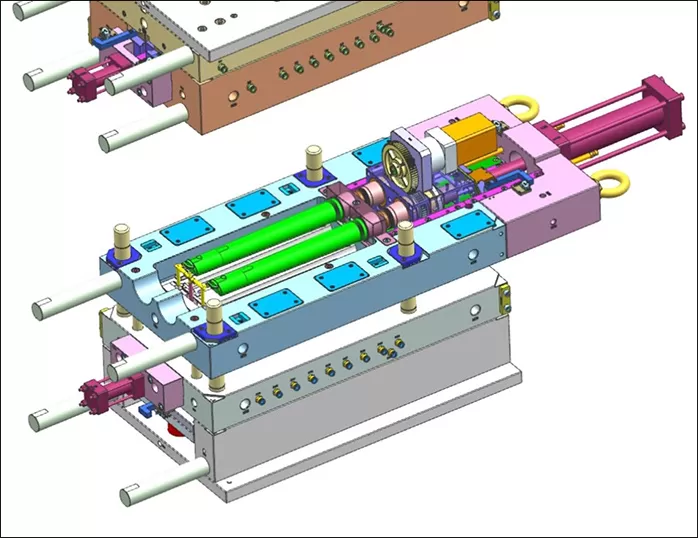

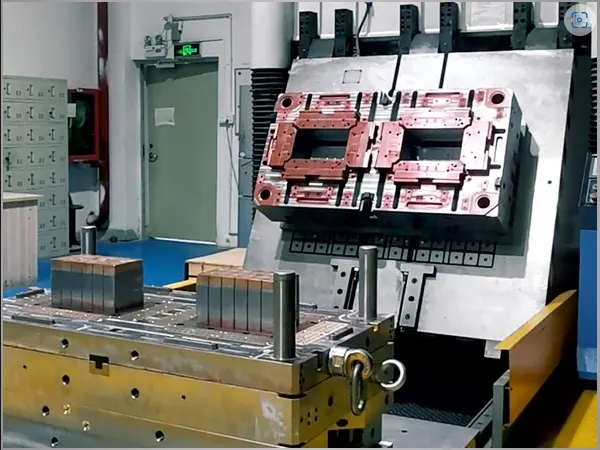

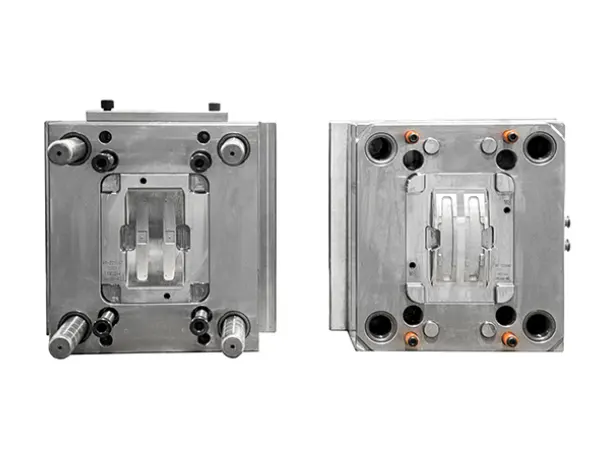

Production StrengthThe company possesses five 5-axis machining centers, including German-made HERMLE C22, C42, and C62 models, as well as over 100 precision mold processing equipment such as AGIE and Sodick EDM machines, Okuma and FANUC machines. Our production workshop is equipped with a constant temperature and humidity control system, ensuring processing accuracy of up to 0.002mm, with a T1 pass rate exceeding 90%.

Production StrengthThe company possesses five 5-axis machining centers, including German-made HERMLE C22, C42, and C62 models, as well as over 100 precision mold processing equipment such as AGIE and Sodick EDM machines, Okuma and FANUC machines. Our production workshop is equipped with a constant temperature and humidity control system, ensuring processing accuracy of up to 0.002mm, with a T1 pass rate exceeding 90%. -

Quality StrengthHXC utilizes industry-leading inspection equipment and technology to control every aspect of the production process, from prototype manufacturing to mass production delivery. We ensure that each production step meets the required standards in a timely manner, enabling the entire production process to proceed smoothly. This approach not only guarantees a high product qualification rate but also shortens the production cycle, significantly reducing time costs. When it comes to production quality, we let the data speak for itself – data is the truth!

Quality StrengthHXC utilizes industry-leading inspection equipment and technology to control every aspect of the production process, from prototype manufacturing to mass production delivery. We ensure that each production step meets the required standards in a timely manner, enabling the entire production process to proceed smoothly. This approach not only guarantees a high product qualification rate but also shortens the production cycle, significantly reducing time costs. When it comes to production quality, we let the data speak for itself – data is the truth!

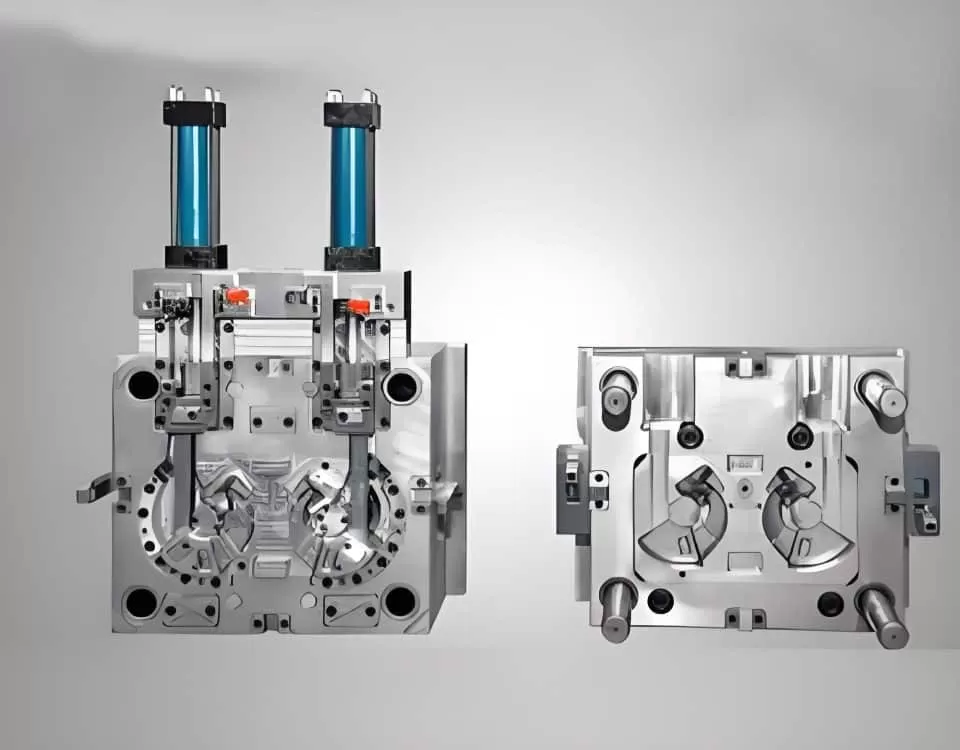

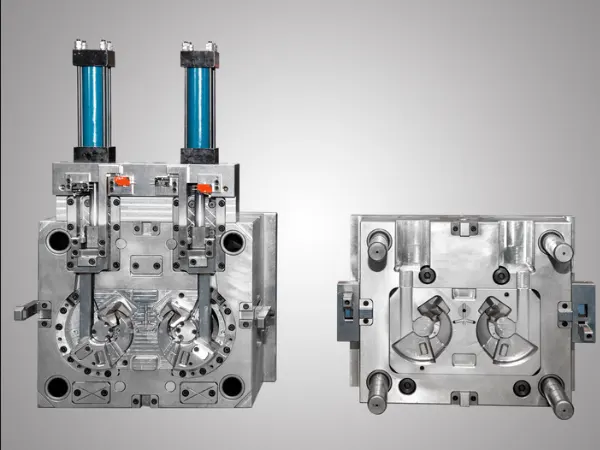

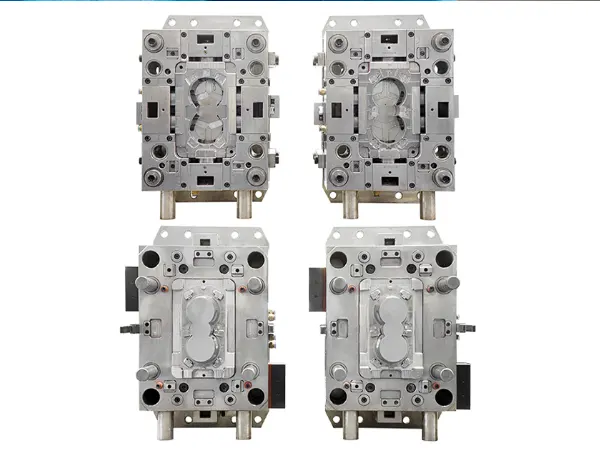

Mould making

20+ years of focus on precision mold, one-stop service to improve efficiency and quality

Special purpose forming

We support your development goals by having no minimum order volumes or value for our injection molding production. In addition and transparent pricing on every project, every time.

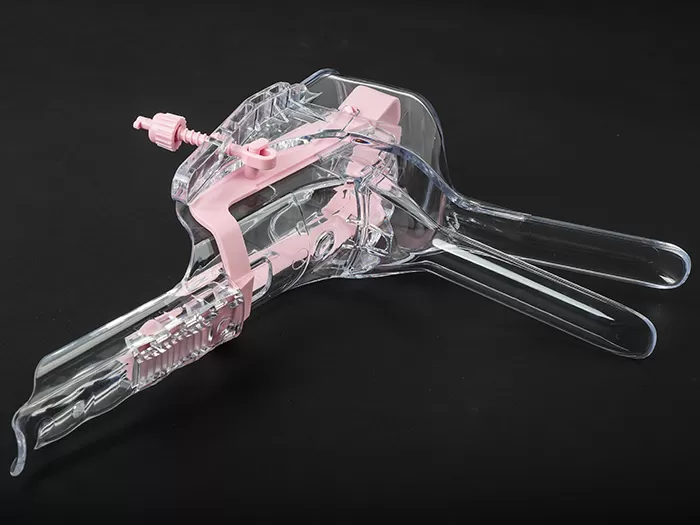

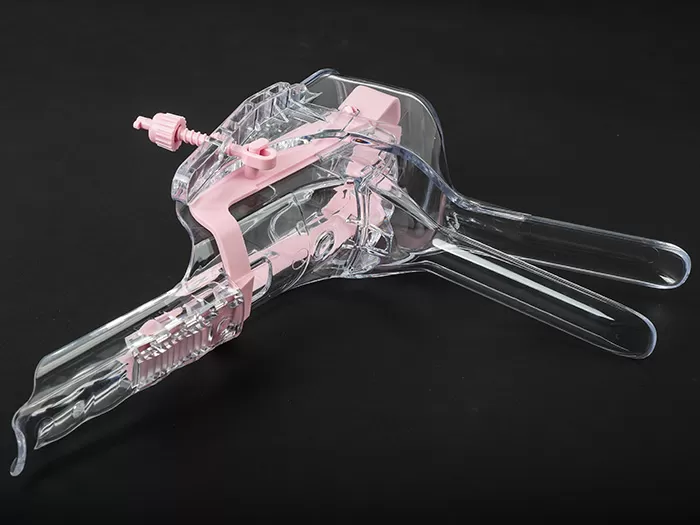

- Medical

- Automobile

- Electronics

- Beautify

- The lamp

- Agriculture

- More cases

-

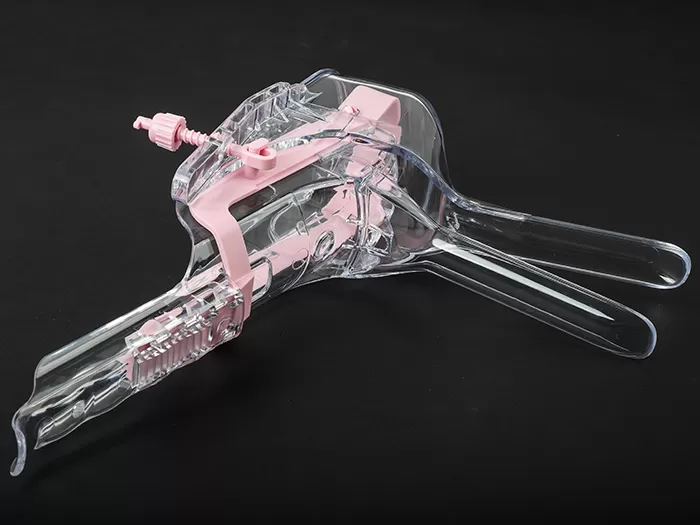

MedicalHXC, as a medical equipment supporting production company for more than ten years, has its own huge advantages in terms of development depth, manufacturing capacity and industry experience. The company has passed the medical ISO13485:2016 certification.

MedicalHXC, as a medical equipment supporting production company for more than ten years, has its own huge advantages in terms of development depth, manufacturing capacity and industry experience. The company has passed the medical ISO13485:2016 certification. -

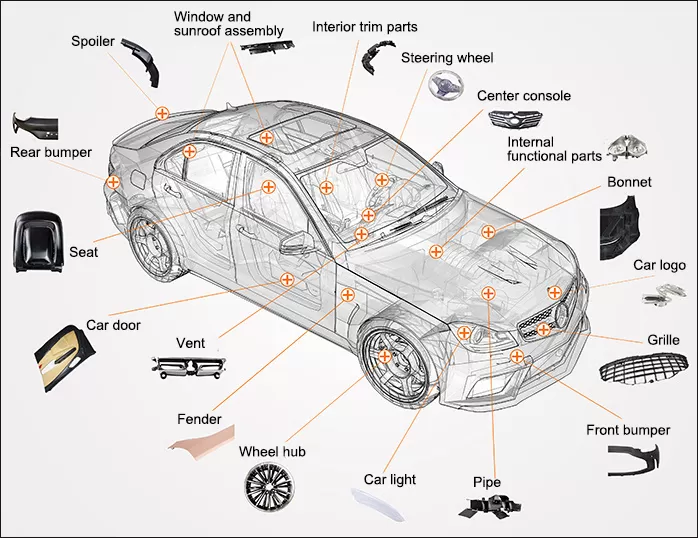

Automobilehe automotive industry is an important customer group of HXC, for which we provide one-stop services from hand plate, mold design, mold manufacturing, mass production, inspection, assembly, and successful delivery. Involving a variety of automotive shell parts, structural and functional parts, interior parts and other comprehensive products, the company has passed the industry IATF 16949 certification.

Automobilehe automotive industry is an important customer group of HXC, for which we provide one-stop services from hand plate, mold design, mold manufacturing, mass production, inspection, assembly, and successful delivery. Involving a variety of automotive shell parts, structural and functional parts, interior parts and other comprehensive products, the company has passed the industry IATF 16949 certification. -

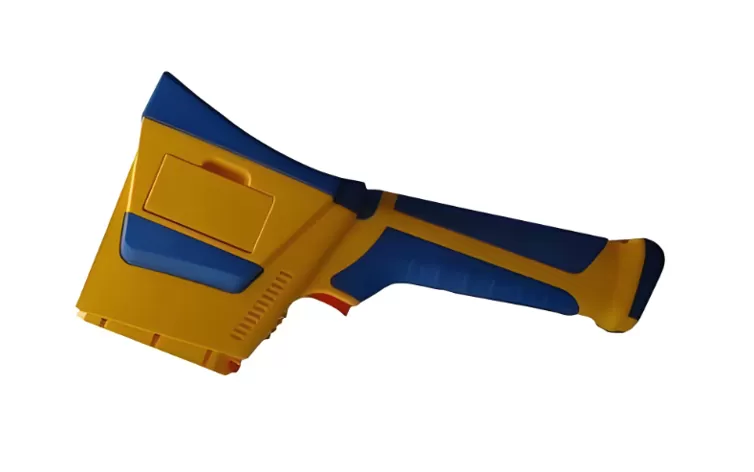

ElectronicsIn modern society, electronic products are everywhere, and most of the plastic parts used are injection molded products. Meiyu Tongrun has 15 years of experience in electronic products precision mold and precision injection molding. Mobile phone shell, electronic products accessories, keyboard keys, two-color mold, etc., are high-end products for export. In design, development and production and processing, we can provide stable, reliable and efficient customized services.

ElectronicsIn modern society, electronic products are everywhere, and most of the plastic parts used are injection molded products. Meiyu Tongrun has 15 years of experience in electronic products precision mold and precision injection molding. Mobile phone shell, electronic products accessories, keyboard keys, two-color mold, etc., are high-end products for export. In design, development and production and processing, we can provide stable, reliable and efficient customized services. -

BeautifyIn modern society, electronic products are everywhere, and most of the plastic parts used are injection molded products. Meiyu Tongrun has 15 years of experience in electronic products precision mold and precision injection molding. Mobile phone shell, electronic products accessories, keyboard keys, two-color mold, etc., are high-end products for export. In design, development and production and processing, we can provide stable, reliable and efficient customized services.

BeautifyIn modern society, electronic products are everywhere, and most of the plastic parts used are injection molded products. Meiyu Tongrun has 15 years of experience in electronic products precision mold and precision injection molding. Mobile phone shell, electronic products accessories, keyboard keys, two-color mold, etc., are high-end products for export. In design, development and production and processing, we can provide stable, reliable and efficient customized services. -

The lampIn the field of art lighting, HXC has been immersed in more than ten years, has a wealth of industry experience, 20+ years, a series of new products on the market, and in the recent past, updated models have also been new on the market.

The lampIn the field of art lighting, HXC has been immersed in more than ten years, has a wealth of industry experience, 20+ years, a series of new products on the market, and in the recent past, updated models have also been new on the market. -

AgricultureModern agricultural production needs high-tech auxiliary energy, a scientific design can make the agricultural process greatly improved, HXC will be the customer's design concept into the actual productivity, in the design and manufacturing to solve a variety of difficult problems, the product successfully on the market.

AgricultureModern agricultural production needs high-tech auxiliary energy, a scientific design can make the agricultural process greatly improved, HXC will be the customer's design concept into the actual productivity, in the design and manufacturing to solve a variety of difficult problems, the product successfully on the market. -

More casesOver the past 20 years, HXC has been proven by the market and has always adhered to technological innovation, and our goal is to better injection molding products for more enterprises around the world.

More casesOver the past 20 years, HXC has been proven by the market and has always adhered to technological innovation, and our goal is to better injection molding products for more enterprises around the world.

The Big Four Core competence

Our Strengths

Intelligent quotation

The intelligent quotation system based on machine learning developed by HXC, which is convenient and fast.

One stop processing

Provide one-stop processing from R&D proofing to mass production, covering hundreds of materials and surface treatment.

360° professional service

Customer manager and professional engineers to provide "1+1" service, 360° to meet your processing needs.

Full inspection shipment

HXC has a professional quality inspection team, before delivery of the parts for 100% full inspection, to ensure that the parts meet your requirements.

HXC Injection Molding Service Case

- Date

- 2024-10-15

- Date

- 2024-10-15

- Date

- 2024-10-19

- Date

- 2024-11-05

.jpg)