What we did

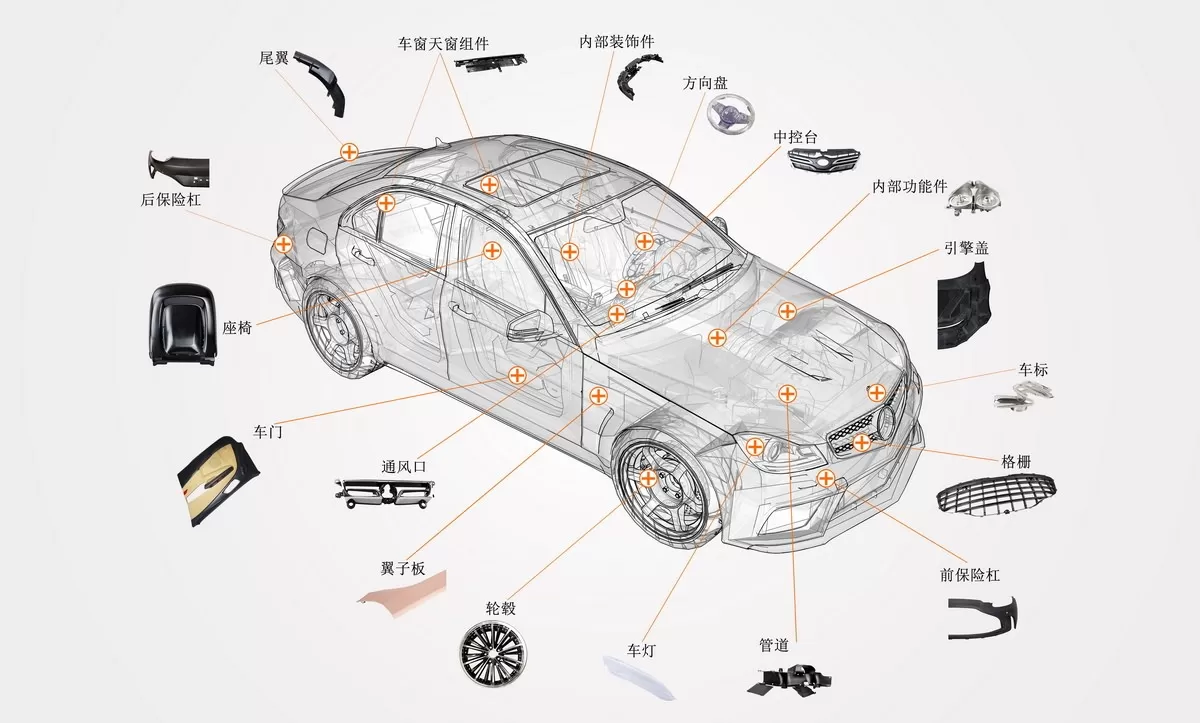

The automotive industry is an important customer group for HXC. We provide one-stop services from prototype, mold design, mold manufacturing, mass production, testing, assembly to successful delivery. Involving all kinds of automotive shell parts, structural functional parts, interior parts and other full-range products, the company has passed the industry IATF 16949 certification.

We make full use of domestic and foreign product design technology, manufacturing technology and production management technology resources, build an international product platform from a high starting point, cooperate with customers to develop new products, and successfully develop new products and mass production for world-renowned brands such as Bentley, Aston Martin, Land Rover, Mercedes-Benz, Audi, Volvo, Volkswagen, DOMETIC, IAC, etc., forming many years of in-depth cooperation, and also laying a solid foundation for the development of HXC in the automotive industry.

Prototype manufacturing

Starting from the prototype, through 3D printing, mold replication, CNC processing, sheet metal and other processes, the official quotation is given within 24 hours, and the fastest delivery is 3-7 days, which quickly verifies the customer's design concept and wins more time for the launch of new products. At the same time, in the production process of the prototype, we work with customers to find and solve problems, and improve the design to pave the way for the smooth mass production of future products.

Car models are updated quickly, new products are continuously launched, and many spare parts are produced. We start verification from the prototype, which has dual requirements for quality and time. At the same time, we must have comprehensive technical strength to meet the different needs of different customers and different products.

HXC has been developing technology for many years, adopting the IPD product development model and scientific process management, and deeply digging from high speed, high quality and cost reduction to seamlessly connect customers' product development cycles. Wasting less materials and other valuable resources on unnecessary prototypes or redesigns will greatly reduce the possibility of redesigning your products when you need to manufacture products.

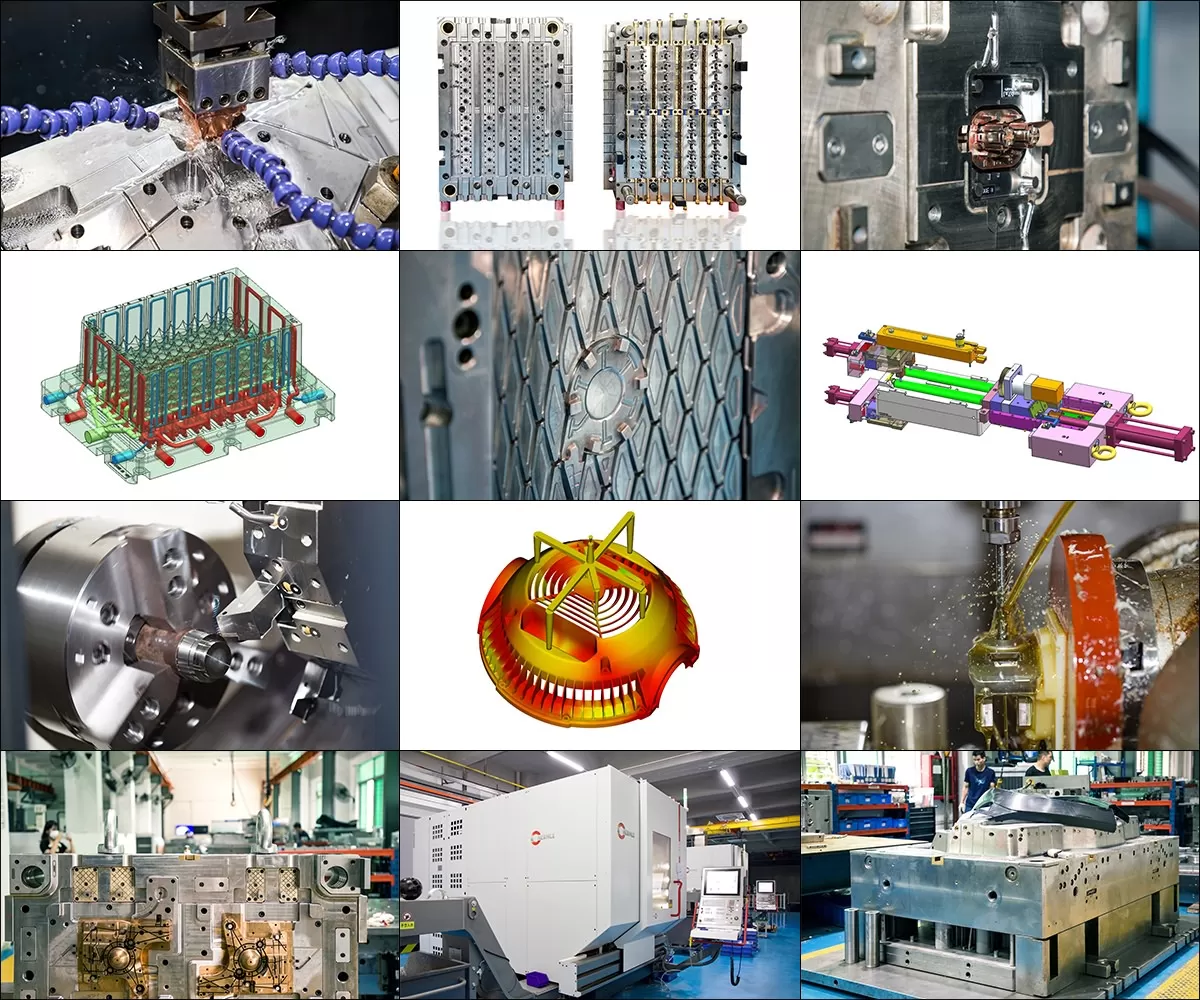

Mould design and manufacturing

HXC has many years of rich experience in mold design and manufacturing. The company's engineering design team has more than 35 people, including veteran designers with more than ten years of experience, as well as high-level talents in Bao'an District, Shenzhen.

HXC has obtained more than 20 national patents. After 15 years of precipitation, it has obvious technical advantages in the same industry in complex mold structure design, high-precision mold design and processing, mold flow analysis, conformal cooling technology, and processing thermal deformation management.

The company has 5 German HERMLE C22, C42, C62 5-axis machining centers, AGIE spark machines, Sodick spark machines, Okuma, FANUC, AgieCharmilles and other precision mold processing equipment, a total of 83 units, and a constant temperature and humidity production workshop. The machining accuracy can reach 0.002mm. The T1 pass rate exceeds 90%.

Mass production

In the mass production stage, hxc conducts mass production through mold design, mold manufacturing, injection molding, machining, die casting, extrusion, stamping and other processes. Through comprehensive surface treatment processes such as polishing, electroplating, oxidation, sandblasting, powder spraying, painting, passivation, electrophoresis, etc., customers' appearance and performance requirements are met.

The company has Sumitomo and Sodick molding injection machines, and high-precision manipulators can automatically perform 24-hour injection molding, ensuring efficient production. The established CMM fully automatic measurement laboratory strictly controls the size and quality.

The company has a team of precision plastic molds and injection molding with rich theoretical and practical experience. The backbone members have more than 20 years of experience in the mold industry and can solve various difficult problems encountered in production, making the entire production process smoother.

Assembly inspection

HXC has an independent and standard assembly production line. Using industry-leading testing equipment and technology, from prototype manufacturing to mass production delivery, we control every link in the production process, so that every production link can meet the standards in time, and the entire production process can proceed smoothly. In general, this not only ensures a high pass rate of the product, but also shortens the production cycle and greatly reduces the time cost.

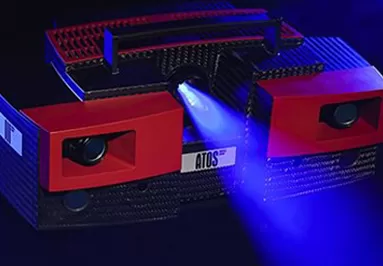

Our testing center has advanced and comprehensive testing equipment such as the German GOM ATOS III TRIPLE Scan blue light 3D scanner, the Swedish Hexagon three-coordinate measuring instrument, the 2.5-dimensional fully automatic image measuring instrument, the Hitachi handheld X-ray fluorescence spectrometer, the Swiss TESA altimeter, and the Japanese Mitutoyo roughness meter to ensure that your products meet the design and functional requirements.

Partners