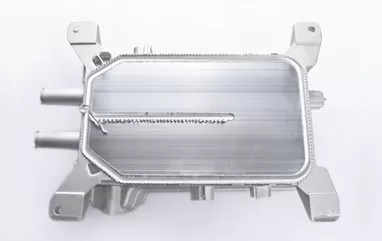

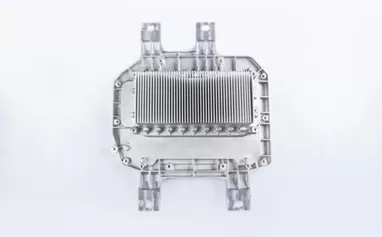

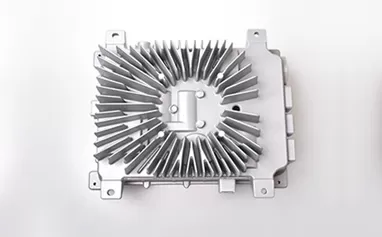

New Energy Precision Die Casting Mold

Nowadays, the design and manufacturing of precision molds are becoming more and more in-depth in all walks of life. Precision molds are the basis of high-precision mass-produced products, and they have also been widely used in the emerging field of new energy vehicles.

New energy vehicles are an emerging industry that the world's automotive industry pays common attention to. There are certain differences in the construction of new energy vehicles among countries, but their fundamental goal is to give full play to the advantages of new energy vehicles, reduce the actual pressure on environmental resources, and promote the sustainable development of the domestic economy. Today, my country's new energy vehicle industry has entered a new stage of rapid development with large scale and high quality. The continuous improvement of supporting service facilities makes new energy vehicles more attractive.

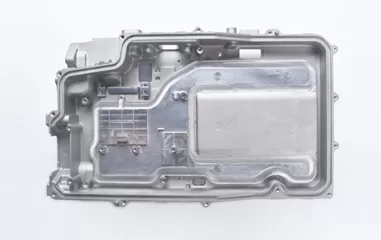

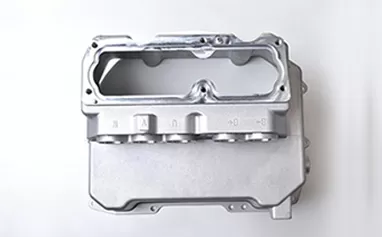

In electric vehicles, charging is one of the most important links. An efficient and stable charging module will undoubtedly provide strong power support for electric vehicles.

Difficulties in mold design and manufacturing technology

In the design and manufacture of molds, we encountered problems of all sizes. Some problems may seem minor, but they will obviously affect the quality of the product, while some serious problems will directly affect the delivery of the product. We have selected some representative problems for analysis, but due to technical confidentiality, we cannot make them fully public. Please understand.

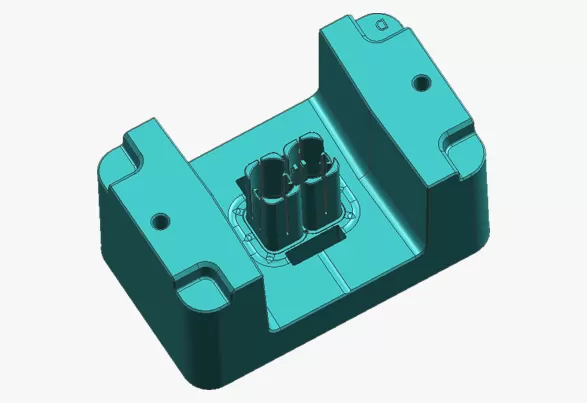

Problem: The product structure is complex and the traditional cooling method cannot meet the requirements. The injection molding cycle is as long as 85 seconds, and the product deformation is large.

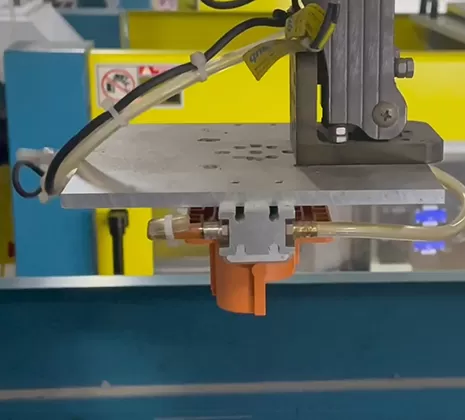

Improvement plan: The mold insert uses 3D printing conformal water channels.

Improvement effect: The deformation is reduced from 0.6mm to between 0.08-0.12, and the injection molding cycle is shortened from 85 seconds to 25 seconds.

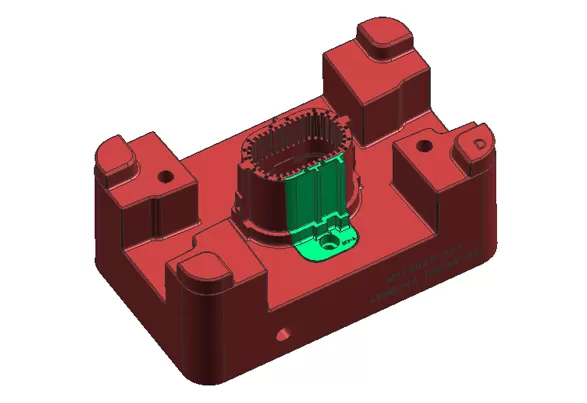

Problem: There are 5 products on the mold. After producing one of them, the mold needs to be removed from the machine to replace the interchangeable inserts, and the mold is dropped from the upper mold, causing downtime.

Improvement plan: The parts are designed to be disassembled from the front, and the mold can be replaced without lowering the mold

Improvement effect: The original replacement time is shortened from 4 hours to 15 minutes.

Problem: The size of the mold insert is 7.4x6.5x51.83mm. The top and middle parts of the insert are inserted and need to be sealed. The insert deforms during the processing. Even if the parts are processed and put into the mold for production, they will still deform after 2000 PCS, making the mold unable to be produced.

Improvement plan: Use special steel for processing, and perform deep cooling process after processing to ensure dimensional stability and no deformation

Improvement effect: The mold insert needs to be replaced after 2000 PCS, but only needs to be replaced after 50,000 PCS after improvement.