Medical industry solutions

Medical care is the most closely related industry to human beings, which determines people's health, lifespan, and quality of life. In modern society, with the help of technology, the development of the medical industry is very rapid, which also brings more opportunities and expectations for the development of human society. The COVID-19 is spreading all over the world, posing a severe test for global medical care, but also urging a greater leap in medical standards.

HXC, as a company with over a decade of experience in the production of medical equipment, has significant advantages in terms of development depth, manufacturing capabilities, and industry experience. It collaborates with globally renowned medical equipment manufacturer Siemens Philips、Seer、 Daan Gene, Bioventus, Sensible Medical, and others have had many years of deep cooperation.

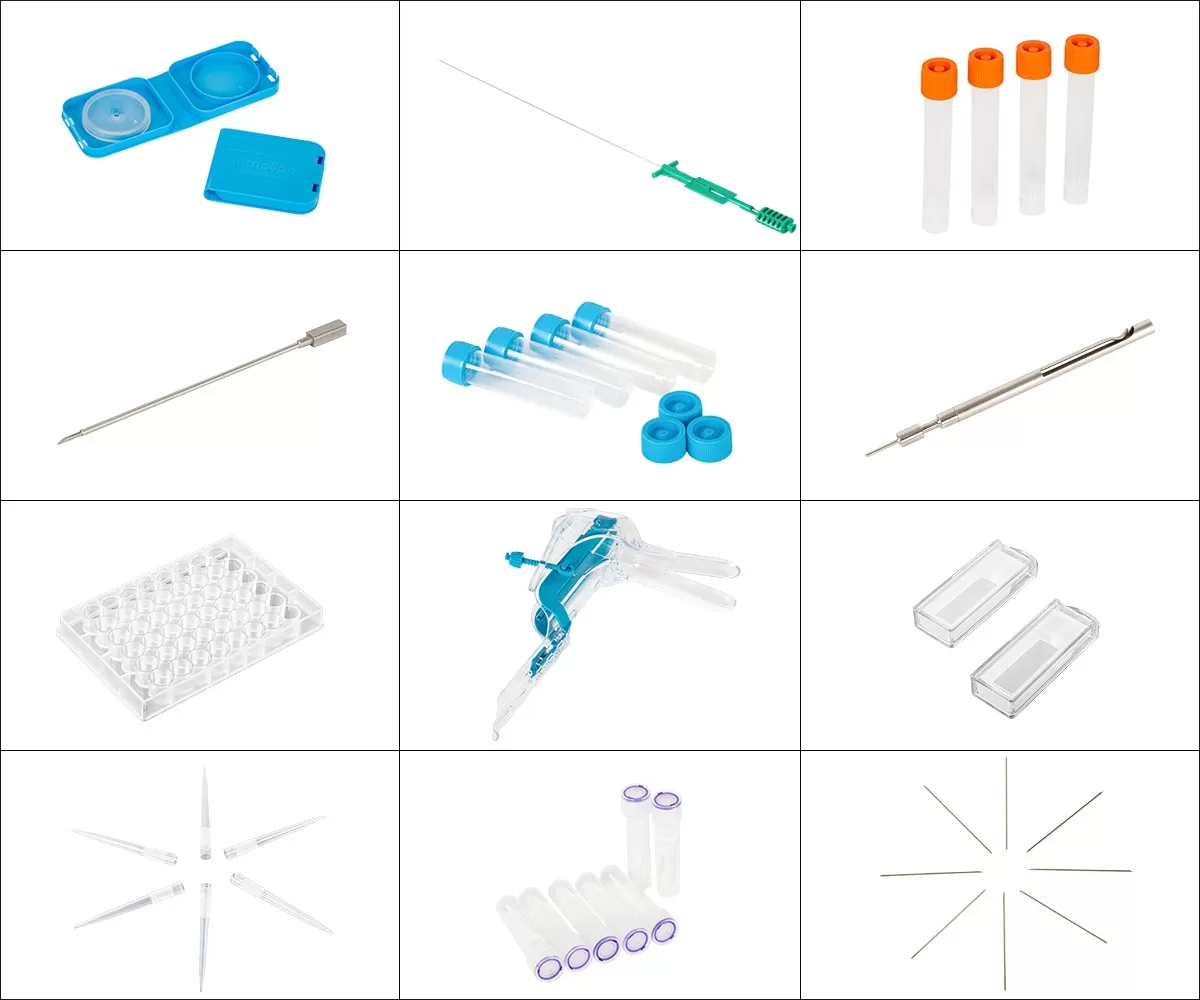

Medical equipment

HXC has been collaborating with global clients for many years to develop a variety of innovative medical devices, which have been applied in various sub sectors of the medical industry.

Among our collaborating medical clients, Seer from Australia has developed a wearable epilepsy diagnostic monitoring device that has been certified by the US FDA. It combines the advantages of devices, cloud computing, and computer science to transition clinical monitoring from hospitals to homes. The product can diagnose and manage neurological, cardiac, and sleep conditions, creating new clinical care pathways, which is a revolutionary technological breakthrough and won the 2021 Reddot Award for it.

During the collaboration with Seer, HXC utilized its R&D and manufacturing capabilities from prototype to mold design and manufacturing, injection molding, and mass production delivery to promptly identify and correct design issues. This made the entire development and production process very smooth, achieving rapid product launch.

In the combination of high-tech and medical equipment applications, HXC has also accumulated valuable experience and closely follows the development trend of future medical equipment.

Medical Consumables

Medical consumables are the most widely used in medical facilities and the products that each of us comes into contact with. They have very high requirements for material, size, accuracy, sealing, dust-free operation, etc. Typically, precision molds and high-precision CNC machining are used.

Plastic tubular products have strict requirements on the uniformity of wall thickness. For example, we produce nucleic acid detection tubes for COVID-19 detection for the domestic listed company Da'an Gene Group. The mold precision is required to reach 0.005mm, and the problem of product glue deviation is also strictly limited. Our excellent engineering team can solve a series of problems encountered in design and production one by one. Now, we have upgraded to precision molds with 48 cavities for pipes and 64 cavities for lids, which greatly improves production efficiency.

Medical consumables have high requirements for manufacturers' comprehensive design, process level, manufacturing capability, production environment, etc. After more than ten years of accumulation, HXC has outstanding capabilities in development, production strength, and scientific management, which can meet various production needs of medical consumables and provide smoother manufacturing.

Health and rehabilitation diagnostic equipment

Health and diagnostic equipment are devices that go before the diagnosis of diseases, and rehabilitation equipment is crucial for improving the long-term quality of life of patients. Some advanced design concepts from around the world have been validated through prototype design in HXC and have been mass-produced and launched.

Just like Bioness, a subsidiary of Bioventus, a publicly traded company in the United States, which uses the wearable knee rehabilitation electrical stimulator L300 Go to relieve pain and improve nerve and muscle health, the new L300 Go improves the main functions of the award-winning Functional Electrical Stimulation (FES) foot lowering and thigh weakness device, providing unparalleled freedom and independence for stroke, multiple illness, sclerosis, spinal cord paralysis, traumatic brain injury or spinal cord injury rehabilitation patients.

The seemingly simple product contains a large number of precision injection molded parts, silicone parts, hardware parts, and coatings, with strict requirements for materials, tolerances, and surfaces. Through the joint efforts of Meiyu Tongrun and Bioventus, the L300 Go has now become a very mature global product.

Like Annabella, an emerging Israeli company, the innovatively designed breast pump simulates the movement of a baby's tongue to induce natural processes and hormone production. More importantly, this greatly enhances the comfort of the mother. A small product consisting of 40 components, made of materials such as PC+ABS, transparent silicone, hard rubber, soft rubber, food grade PP, etc. The process includes injection molding, encapsulation molding of soft and hard rubber, and blow molding. Meiyu Tongrun provides comprehensive one-stop industrial manufacturing services from prototype production to mass production, as well as product assembly and delivery.

Medical Accessories

HXC provides customized one-stop industrial manufacturing services for various medical equipment processing accessories, from prototype to mass production, from plastic parts to metal parts, using CNC machining, 3D printing, sheet metal, injection molding, replication, stamping, die-casting, extrusion and other processes to meet the product needs of global customers. Especially for products and enterprises that intend to put their product concepts into mass production and launch, our one-stop service can greatly improve efficiency and quality, reduce costs, and significantly shorten the time for product launch.

Mass production assembly

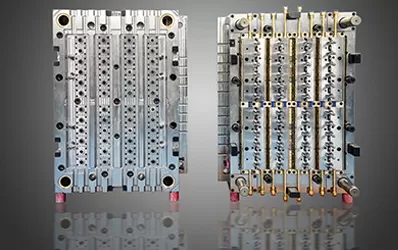

HXC has 5 German HERMLE C22, C42, C62 5-axis machining centers, AGIE spark machines, Sodick spark machines, Okuma, FANUC and other precision mold processing equipment, and a constant temperature and humidity production workshop. The processing accuracy can reach 0.002mm, and the T1 qualification rate exceeds 90%. A strong team of mold designers with over ten years of experience in precision mold design and operators with over 20 years of experience, produce thousands of finished molds annually and send them to various parts of the world.

HXC has independent and standardized assembly production lines, as well as a 100000 level dust-free workshop. We have injection molding machines such as Sumitomo and Shadick, and can process large quantities of injection molds, two-color molds, and encapsulation molds. We have strong production capacity and produce over 30 million injection molded products annually.

Mass production assembly