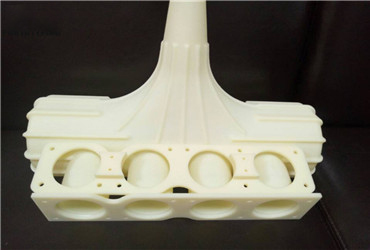

Prototype Model – Tesla Push Rod Case

2025-04-29

Audio Speaker Speaker Panel Accessories Case

2025-04-30Vacuum Remake - Automotive Tail Light Product Case

Customer requirements:

1、 Produce 1 set of full-size automotive engine accessories for assembly and performance testing

Delivery within 2 days

2、 Foreign customer car taillight products, vacuum replica, semi transparent effect

Delivery within 7 days

Solution:

1. The accuracy reaches+/-0.1mm, and the 0.02 layer thickness fully meets the size design verification requirements

2. Using PA3200 nylon mixed with fiberglass material, it has high strength, high toughness, and high temperature resistance, fully meeting the functional design verification requirements

3. All components are produced and printed in one go without splicing, while ensuring the strength of the parts, completely surpassing traditional manufacturing methods

4. Short processing cycle, completing sample processing in 12 hours, greatly shortening the R&D cycle and significantly reducing product costs

1. According to customer requirements, develop a production plan that requires the use of vacuum replication technology.

2. 3D printing prototype prototype, post-processing, and preparation before mold opening

3. Making silicone molds takes about half a day

4. Copy the product, with a production cycle of approximately 8 hours, and reuse the mold 5 times

5. Post treatment polishing, sandblasting effect, and production of perfect surface treatment process