定制高精度注塑零部件制造商

高精度注塑件定制制造商

HXC 在模具制造和注塑行业拥有 20 余年经验。

我们坚持 “客户至上,服务驱动” 的理念,持续完善制造服务,专注于高精度模具定制加工,提供精密注塑产品生产服务,包括模具设计、模具制造、注塑成型、表面处理、产品组装包装一站式 OEM/ODM 定制服务。

二十年来,HXC 经市场验证,始终坚持技术创新,致力于为全球更多企业提供高精度模具。

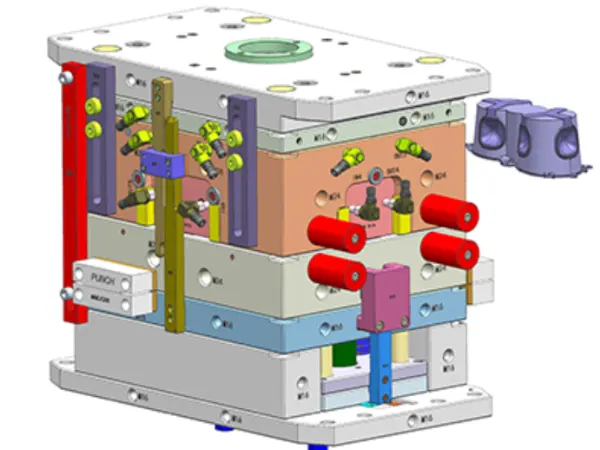

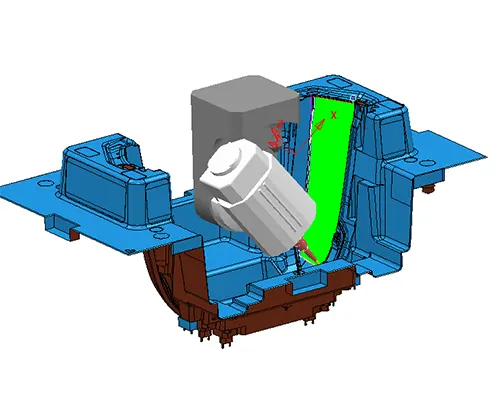

- 我们专注于注塑模具解决方案的研发,通过开发更高效、更贴近客户需求的解决方案与技术,在双色成型、三色成型、气辅应用、高光成型等领域拥有前沿技术。

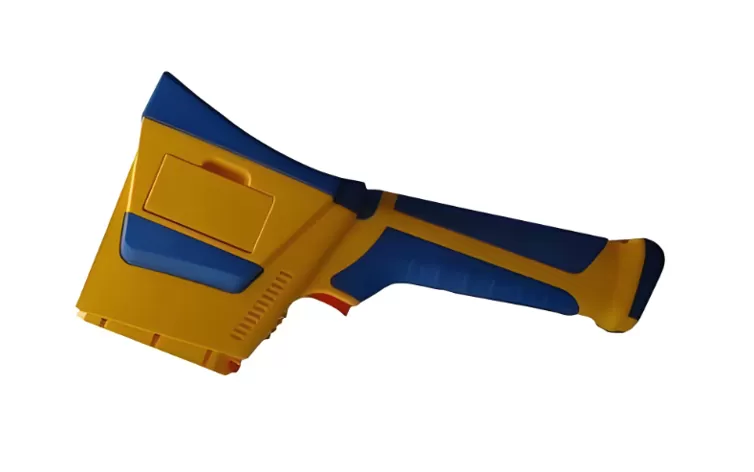

- 同时,基于卓越的生产能力,我们为客户提供电镀产品、高光产品、多色产品、食品医疗级产品、大型制品等精密产品。

- 从模流分析和 DFM 分析到注塑工艺,由经验丰富的工程师团队提供强力支持,确保项目成功。

- 我们将您的创意转化为精准原型,通过 3D 打印、CNC 加工和注塑成型等技术加速产品开发,帮助您快速测试和验证零部件,确保设计从概念顺利落地市场。凭借高精度加工实现设计的快速迭代优化是我们的优势,确保原型完全符合您的要求。了解更多。

Develop strength

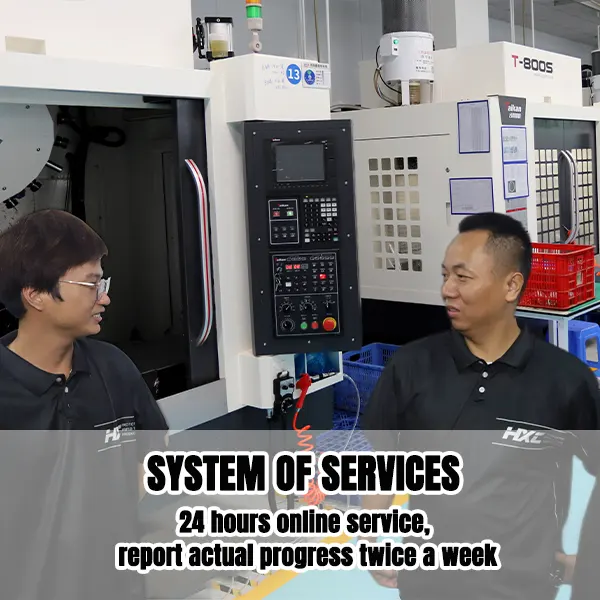

Adhering to the service-oriented growth concept to provide one-stop manufacturing solutions services

-

R&D StrengthWith over 20 years of innovative ideas, HXC has been steadily growing. We have always adhered to the concept of building new products based on customer needs. Our flexible cross-functional teams, organized into project groups, execute new product development tasks. Adopting the IPD (Integrated Product Development) model, we collaborate as a team, putting customer needs at the center, prioritizing customer demands, development, and the fierce market competition, and integrating technology with customer perceptions within our execution team.

R&D StrengthWith over 20 years of innovative ideas, HXC has been steadily growing. We have always adhered to the concept of building new products based on customer needs. Our flexible cross-functional teams, organized into project groups, execute new product development tasks. Adopting the IPD (Integrated Product Development) model, we collaborate as a team, putting customer needs at the center, prioritizing customer demands, development, and the fierce market competition, and integrating technology with customer perceptions within our execution team. -

Design StrengthOur company boasts an engineering design team of over 35 members, including seasoned designers with over a decade of experience and high-level talents recognized by the city of Shenzhen. HXC has obtained more than 20 national patents, and after over 20 years of accumulation, we possess significant technical advantages in the industry.

Design StrengthOur company boasts an engineering design team of over 35 members, including seasoned designers with over a decade of experience and high-level talents recognized by the city of Shenzhen. HXC has obtained more than 20 national patents, and after over 20 years of accumulation, we possess significant technical advantages in the industry. -

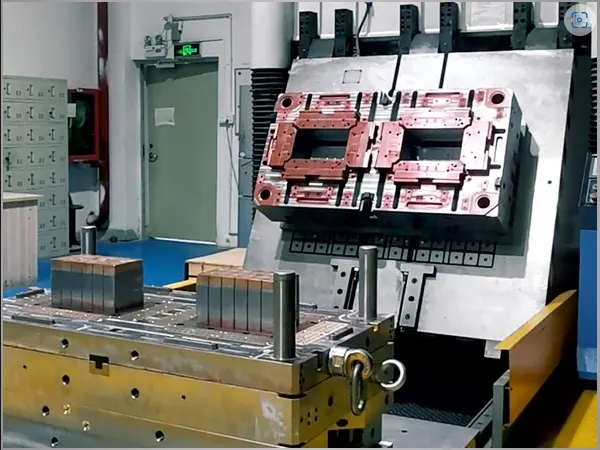

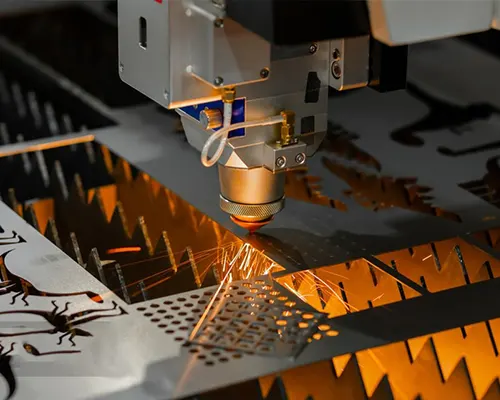

Production StrengthThe company possesses five 5-axis machining centers, including German-made HERMLE C22, C42, and C62 models, as well as over 100 precision mold processing equipment such as AGIE and Sodick EDM machines, Okuma and FANUC machines. Our production workshop is equipped with a constant temperature and humidity control system, ensuring processing accuracy of up to 0.002mm, with a T1 pass rate exceeding 90%.

Production StrengthThe company possesses five 5-axis machining centers, including German-made HERMLE C22, C42, and C62 models, as well as over 100 precision mold processing equipment such as AGIE and Sodick EDM machines, Okuma and FANUC machines. Our production workshop is equipped with a constant temperature and humidity control system, ensuring processing accuracy of up to 0.002mm, with a T1 pass rate exceeding 90%. -

Quality StrengthHXC utilizes industry-leading inspection equipment and technology to control every aspect of the production process, from prototype manufacturing to mass production delivery. We ensure that each production step meets the required standards in a timely manner, enabling the entire production process to proceed smoothly. This approach not only guarantees a high product qualification rate but also shortens the production cycle, significantly reducing time costs. When it comes to production quality, we let the data speak for itself – data is the truth!

Quality StrengthHXC utilizes industry-leading inspection equipment and technology to control every aspect of the production process, from prototype manufacturing to mass production delivery. We ensure that each production step meets the required standards in a timely manner, enabling the entire production process to proceed smoothly. This approach not only guarantees a high product qualification rate but also shortens the production cycle, significantly reducing time costs. When it comes to production quality, we let the data speak for itself – data is the truth!

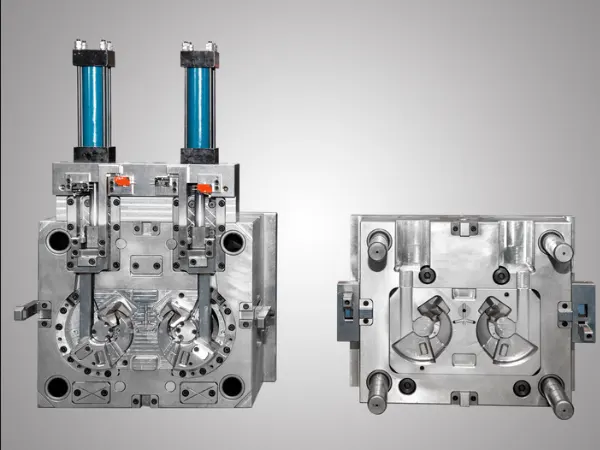

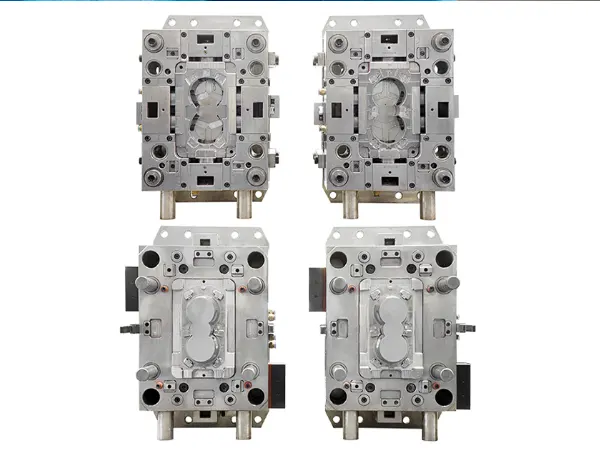

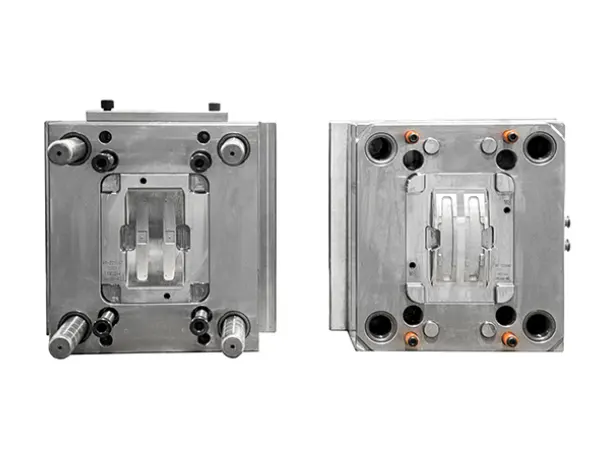

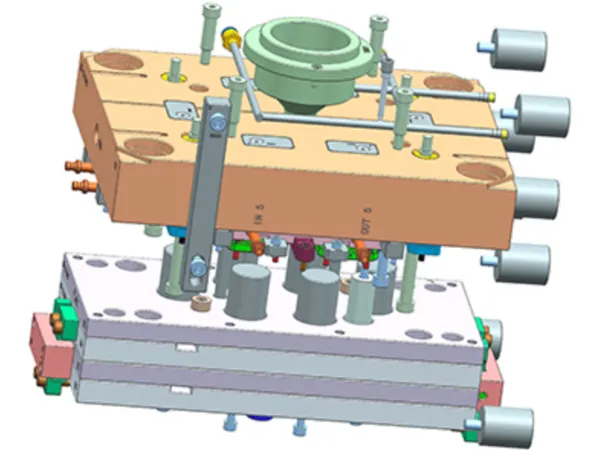

模具制造

20 余年专注精密模具,聚沙成塔,敢为人先,一站式服务提升效率与品质

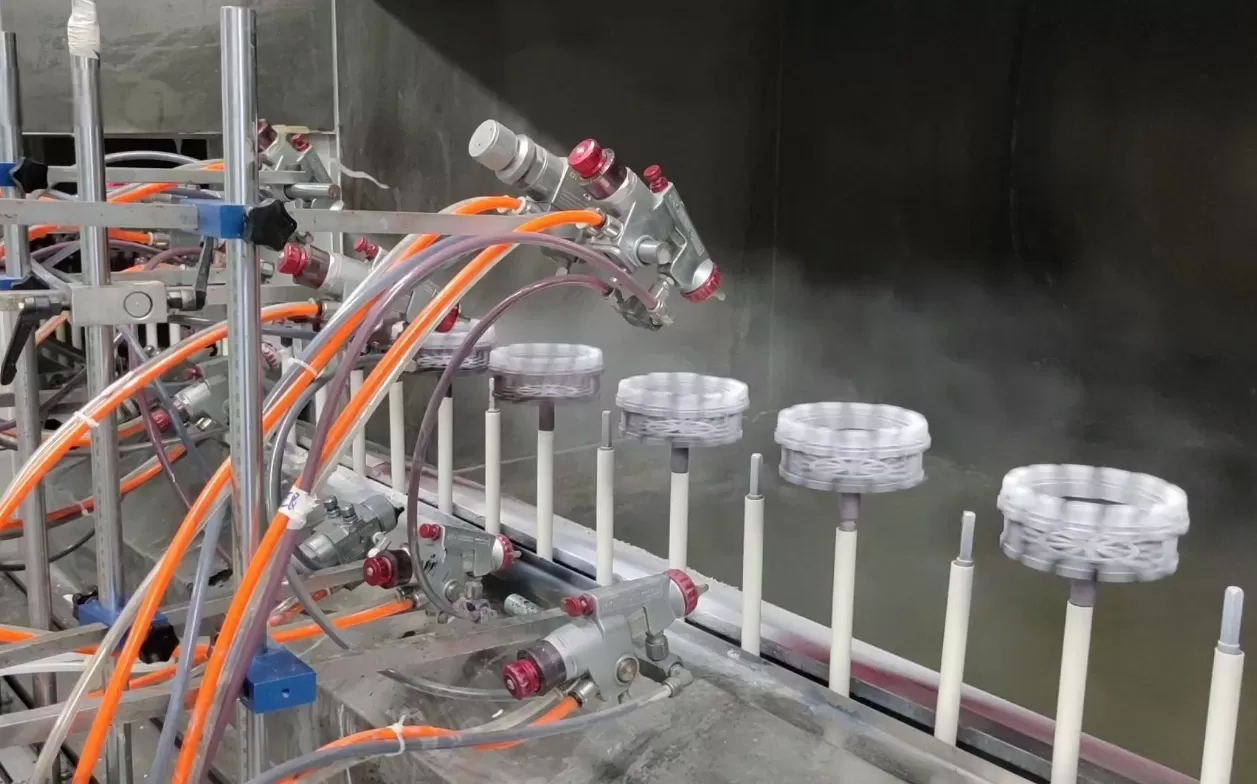

Injection molding processing

With an annual production capacity of over 60 million pieces, we pay attention to details, confront problems directly, and provide professional assistance. We understand our customers best. We are equipped with more than 200 precision injection molding machines imported from Japan and Germany, as well as a medical-grade dust-free injection molding workshop. The fully automatic robotic arms can operate continuously for 24 hours, ensuring high-efficiency, high-consistency, and high-quality mass production.

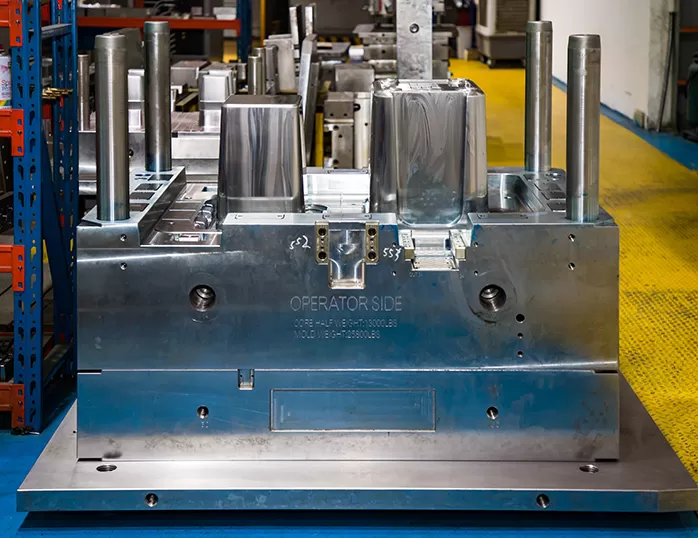

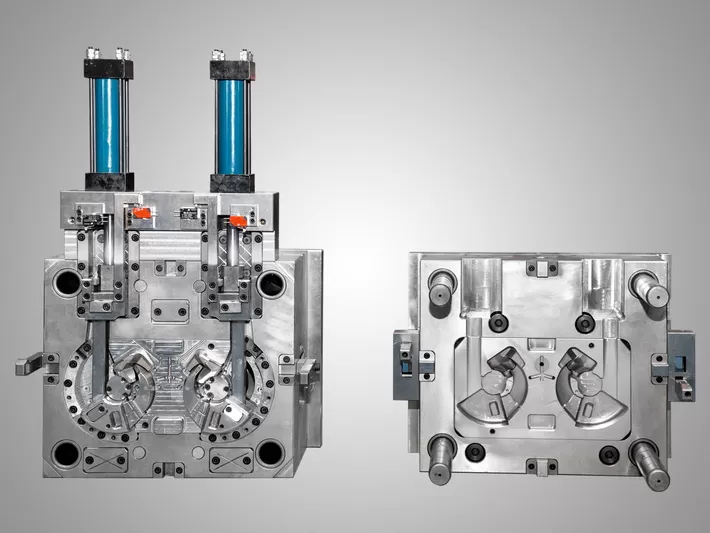

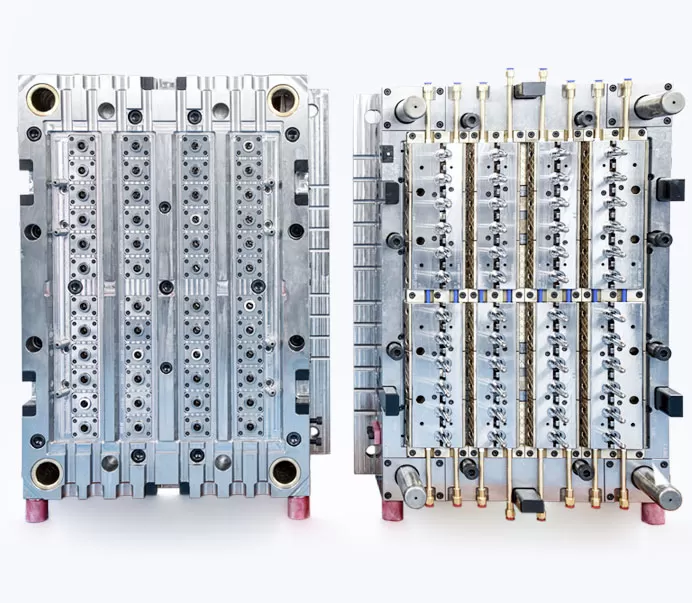

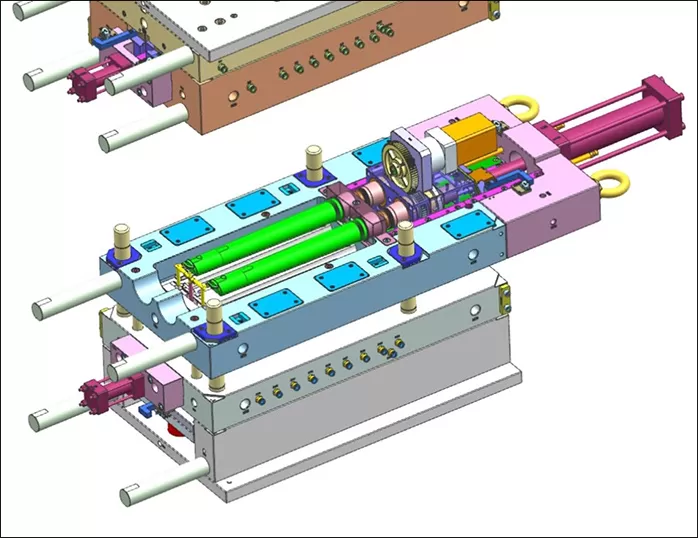

Mold manufacturing

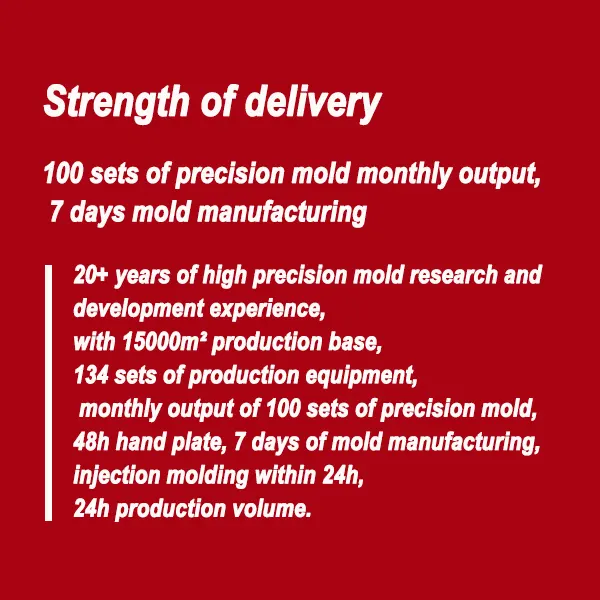

We have over 20 years of experience in precision mold manufacturing and are equipped with a complete set of mold manufacturing equipment, including 187 precision devices such as Swiss 5-axis CNC machines, Japanese CNC-EDM machines, and CMMs from German company ZEISS. Additionally, with more than 70 experienced engineers, we provide customers with comprehensive services ranging from product auxiliary design to mold manufacturing.Our mold delivery time can be adjusted according to different mold specifications, enabling rapid manufacturing. We can produce hand samples within 8 hours, quick molds within 5-10 days, formal molds within 20-25 days, and precision molds within 25-30 days. We achieved the goal of delivering 1,000 sets of molds annually as early as 2020.

特殊成型工艺

我们的注塑生产不设最小订单量或金额限制,支持您的发展目标。此外,每个项目每次均提供透明定价。

- Medical

- Automobile

- Electronics

- Beautify

- The lamp

- Agriculture

- More cases

-

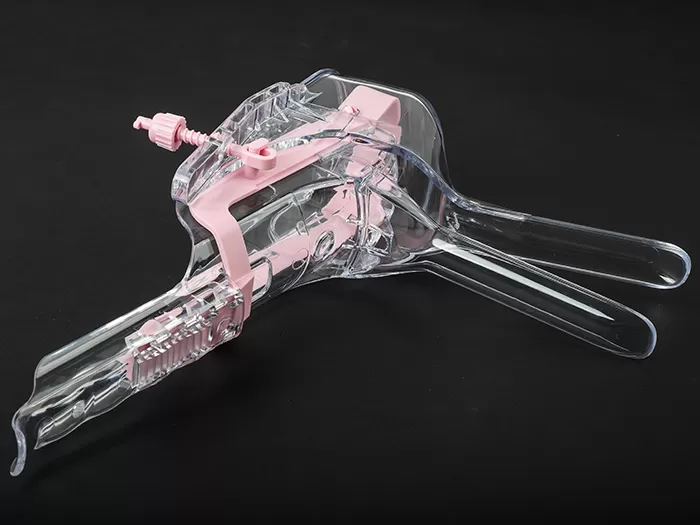

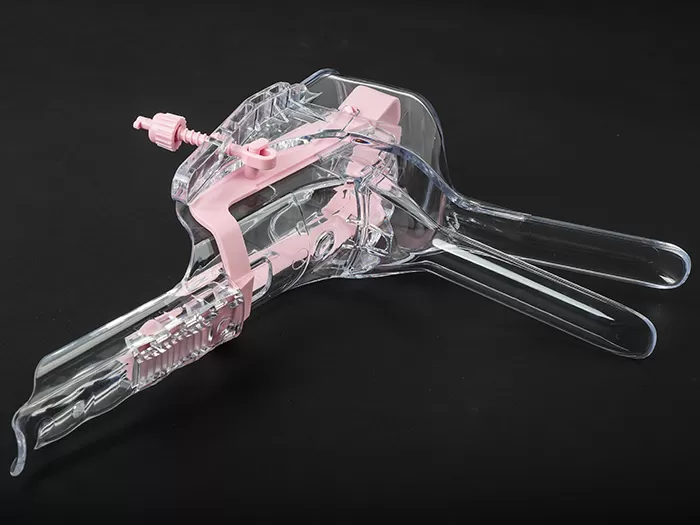

MedicalHXC, as a medical equipment supporting production company for more than ten years, has its own huge advantages in terms of development depth, manufacturing capacity and industry experience. The company has passed the medical ISO13485:2016 certification.

MedicalHXC, as a medical equipment supporting production company for more than ten years, has its own huge advantages in terms of development depth, manufacturing capacity and industry experience. The company has passed the medical ISO13485:2016 certification. -

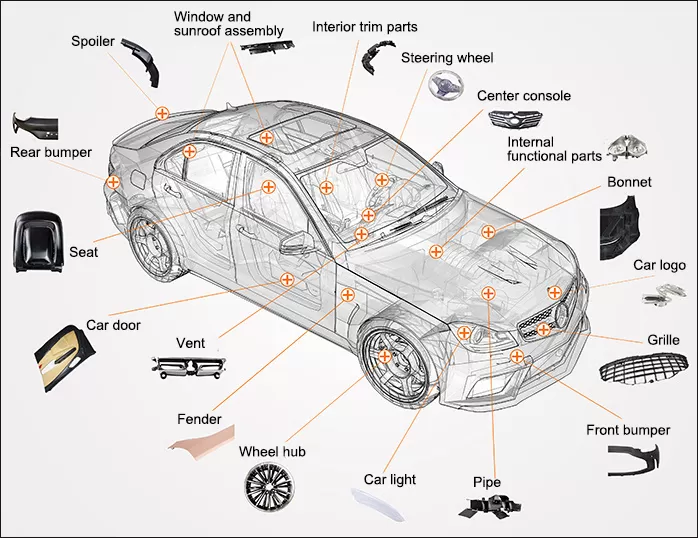

Automobilehe automotive industry is an important customer group of HXC, for which we provide one-stop services from hand plate, mold design, mold manufacturing, mass production, inspection, assembly, and successful delivery. Involving a variety of automotive shell parts, structural and functional parts, interior parts and other comprehensive products, the company has passed the industry IATF 16949 certification.

Automobilehe automotive industry is an important customer group of HXC, for which we provide one-stop services from hand plate, mold design, mold manufacturing, mass production, inspection, assembly, and successful delivery. Involving a variety of automotive shell parts, structural and functional parts, interior parts and other comprehensive products, the company has passed the industry IATF 16949 certification. -

ElectronicsIn modern society, electronic products are everywhere, and most of the plastic parts used are injection molded products. Meiyu Tongrun has 15 years of experience in electronic products precision mold and precision injection molding. Mobile phone shell, electronic products accessories, keyboard keys, two-color mold, etc., are high-end products for export. In design, development and production and processing, we can provide stable, reliable and efficient customized services.

ElectronicsIn modern society, electronic products are everywhere, and most of the plastic parts used are injection molded products. Meiyu Tongrun has 15 years of experience in electronic products precision mold and precision injection molding. Mobile phone shell, electronic products accessories, keyboard keys, two-color mold, etc., are high-end products for export. In design, development and production and processing, we can provide stable, reliable and efficient customized services. -

BeautifyIn modern society, electronic products are everywhere, and most of the plastic parts used are injection molded products. Meiyu Tongrun has 15 years of experience in electronic products precision mold and precision injection molding. Mobile phone shell, electronic products accessories, keyboard keys, two-color mold, etc., are high-end products for export. In design, development and production and processing, we can provide stable, reliable and efficient customized services.

BeautifyIn modern society, electronic products are everywhere, and most of the plastic parts used are injection molded products. Meiyu Tongrun has 15 years of experience in electronic products precision mold and precision injection molding. Mobile phone shell, electronic products accessories, keyboard keys, two-color mold, etc., are high-end products for export. In design, development and production and processing, we can provide stable, reliable and efficient customized services. -

The lampIn the field of art lighting, HXC has been immersed in more than ten years, has a wealth of industry experience, 20+ years, a series of new products on the market, and in the recent past, updated models have also been new on the market.

The lampIn the field of art lighting, HXC has been immersed in more than ten years, has a wealth of industry experience, 20+ years, a series of new products on the market, and in the recent past, updated models have also been new on the market. -

AgricultureModern agricultural production needs high-tech auxiliary energy, a scientific design can make the agricultural process greatly improved, HXC will be the customer's design concept into the actual productivity, in the design and manufacturing to solve a variety of difficult problems, the product successfully on the market.

AgricultureModern agricultural production needs high-tech auxiliary energy, a scientific design can make the agricultural process greatly improved, HXC will be the customer's design concept into the actual productivity, in the design and manufacturing to solve a variety of difficult problems, the product successfully on the market. -

More casesOver the past 20 years, HXC has been proven by the market and has always adhered to technological innovation, and our goal is to better injection molding products for more enterprises around the world.

More casesOver the past 20 years, HXC has been proven by the market and has always adhered to technological innovation, and our goal is to better injection molding products for more enterprises around the world.

四大核心能力

我们的优势

HXC 注塑服务案例

- Date

- 2024-10-15

- Date

- 2024-10-19

- Date

- 2024-11-16

- Date

- 2025-02-25

- Date

- 2025-03-04

- Date

- 2025-03-04

.jpg)