Casos de processamento de protótipos automotivos – Estrutura de farol

2025-04-14

Soluções profissionais e confiáveis de moldes de duas cores e moldeagem por injeção

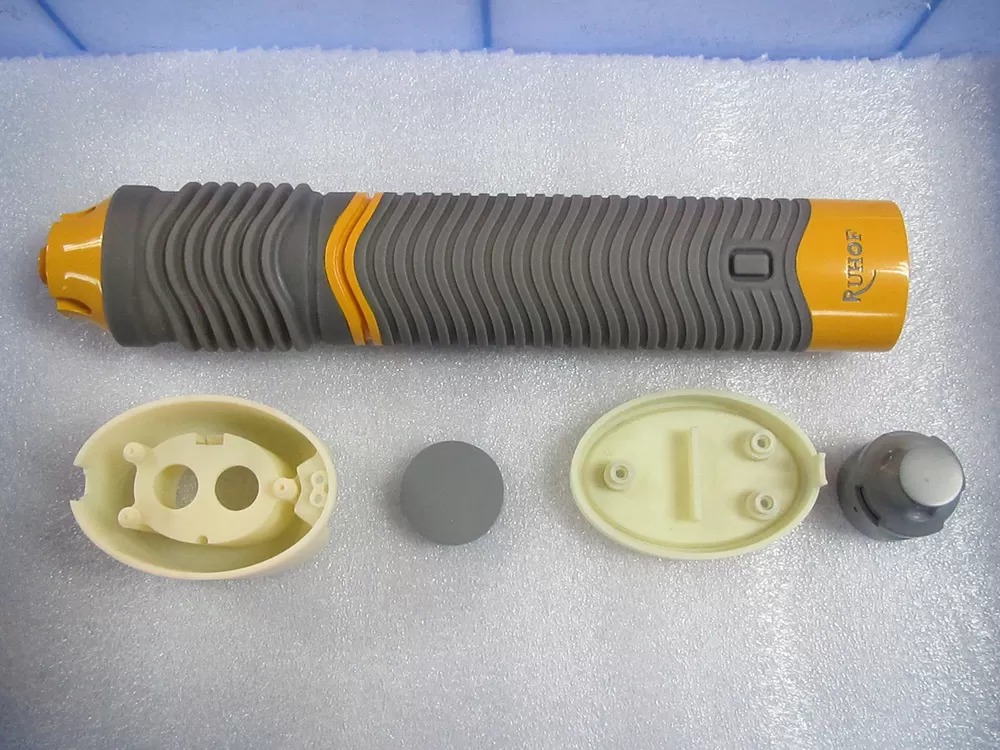

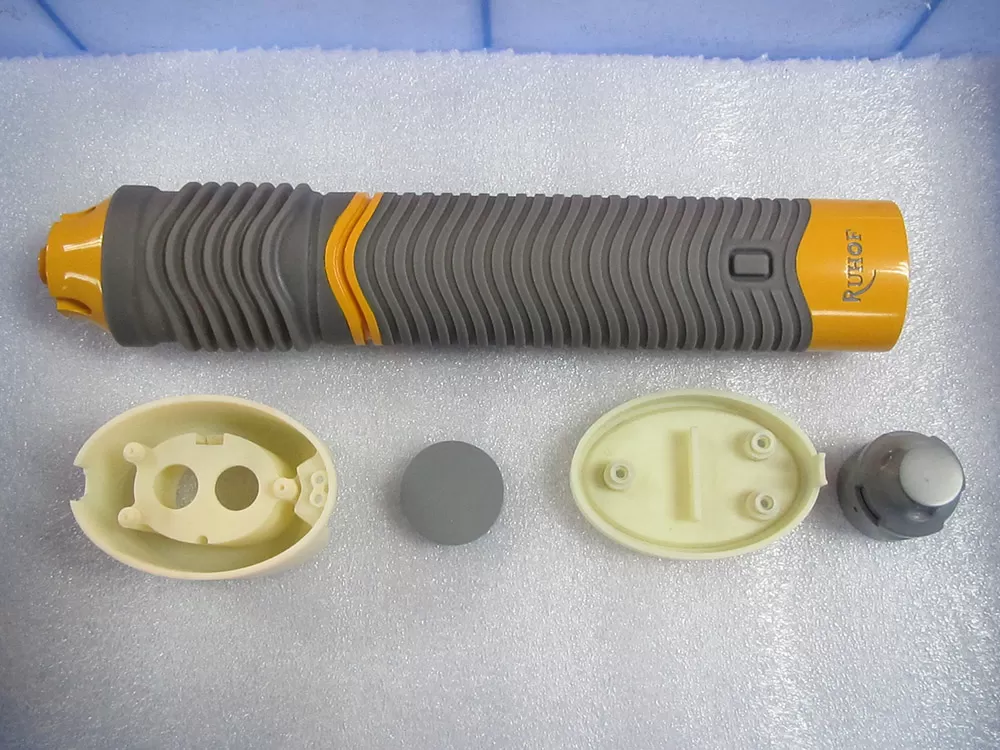

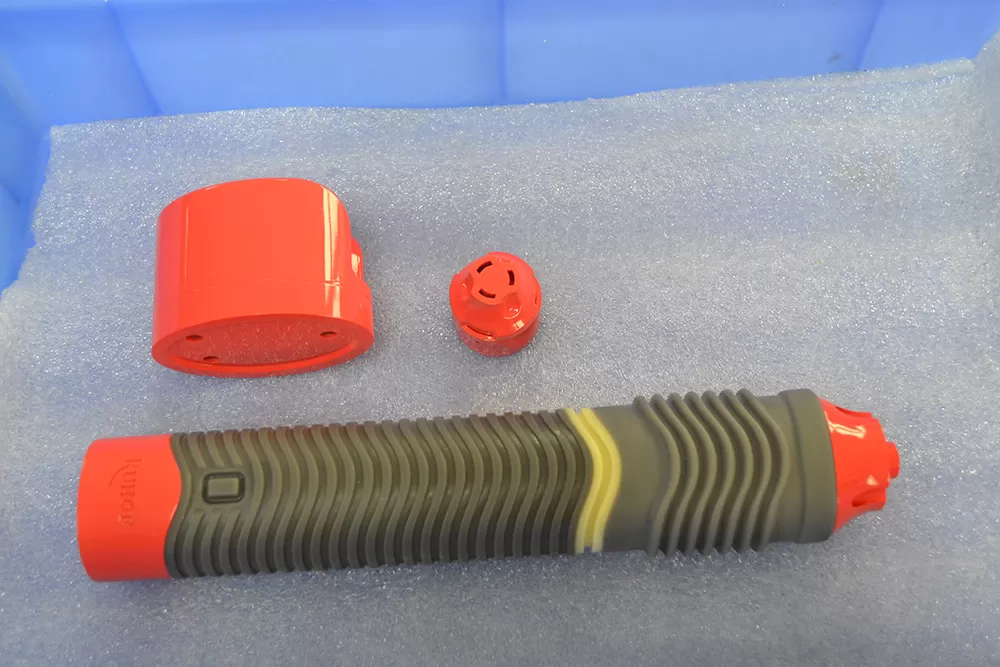

2025-04-16Casos de Protótipo - Limpador Médico

Introdução do Caso

The prototyping of medical cleaners is a professional process involving multiple steps and sophisticated techniques. Here is the general process of prototyping:

Estágio de design: É necessário um design detalhado com base nos requisitos funcionais e de aparência do limpador médico. Este estágio geralmente requer o uso de software profissional de design 3D para criar um modelo digital do produto.

Protótipo: Após a conclusão do design, é necessário produzir um protótipo do produto. Este protótipo é geralmente usado para verificar a viabilidade do design e como referência para o processamento subsequente.

CNC : O processamento CNC é um método comum de fabricação de protótipos que utiliza instruções programadas para controlar máquinas-ferramenta, removendo material com precisão e produzindo peças com dimensões exatas e formatos complexos. A usinagem CNC pode processar diversos materiais, como ABS, PC, PMMA, alumínio e cobre, os quais possuem boa tenacidade e resistência.

Pós-processamento: Após a finalização do processamento CNC, geralmente é necessário um pós-processamento manual, incluindo polimento, pintura, impressão, etc., para garantir a qualidade superficial e a estética do modelo protótipo.

Duplicação em silicone: Caso necessite produzir múltiplos conjuntos de protótipos, a tecnologia de duplicação em silicone pode ser utilizada.

Controle de qualidade: Durante todo o processo de usinagem, é necessário um controle de qualidade rigoroso para garantir que cada etapa atenda aos requisitos de design e às normas da indústria.

Entrega ao cliente: Após concluir todas as etapas de processamento, o modelo protótipo é entregue ao cliente para testes e verificação finais.

Ao escolher um fornecedor apropriado, você pode considerar empresas que oferecem serviços em one-stop, como a HXC, que fornece uma série de soluções completas, desde o design até protótipos, processamento CNC, etc.

Em resumo, o prototipagem de limpadores médicos é um processo complexo que combina design moderno e tecnologia de fabricação de precisão, e exige uma equipe profissional e equipamentos específicos para ser concluído. Através desse processo, é garantido que o design do limpador médico seja totalmente verificado e otimizado antes da produção real.