汽车原型加工案例前照灯框架

2025-04-14

专业可靠的双色模具和注塑解决方案

2025-04-16原型案例医用清洁剂

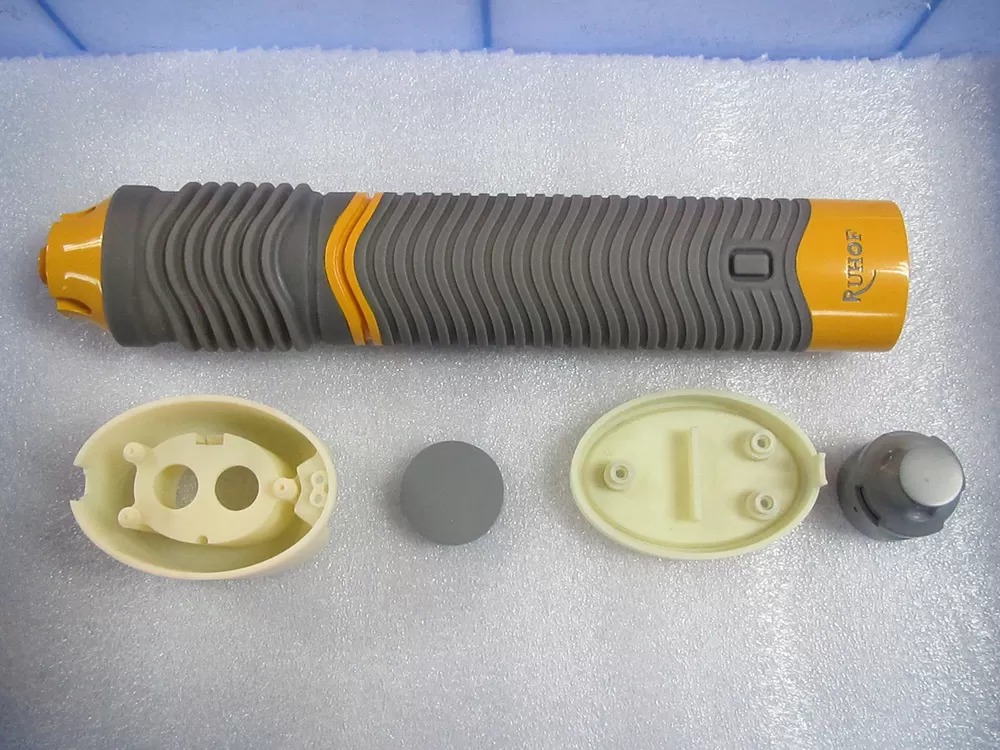

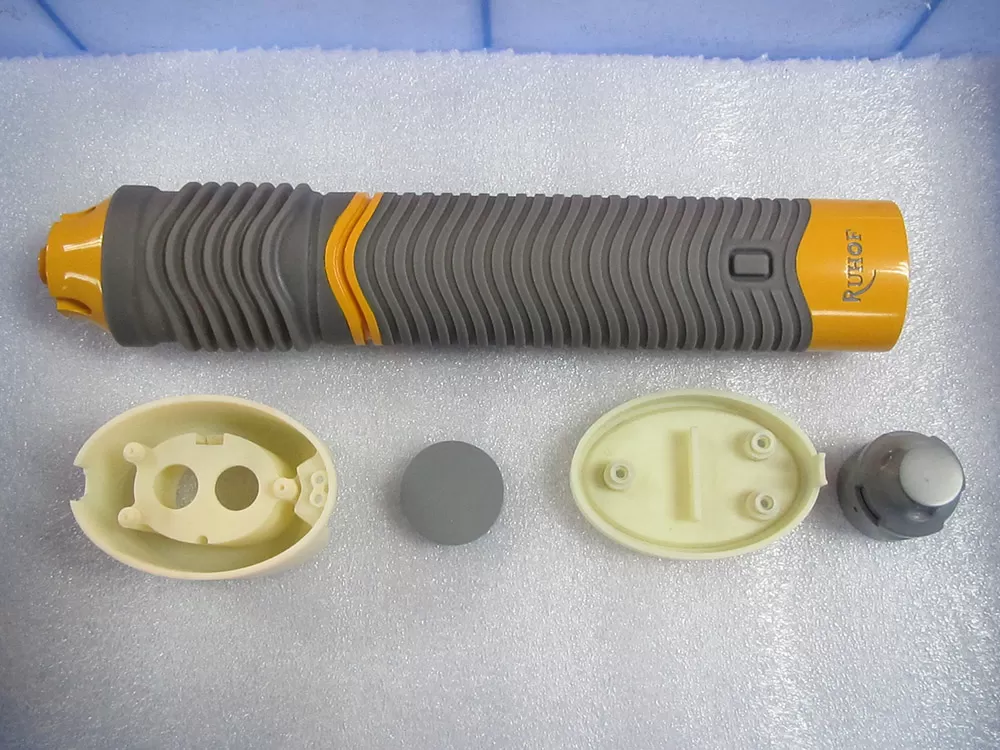

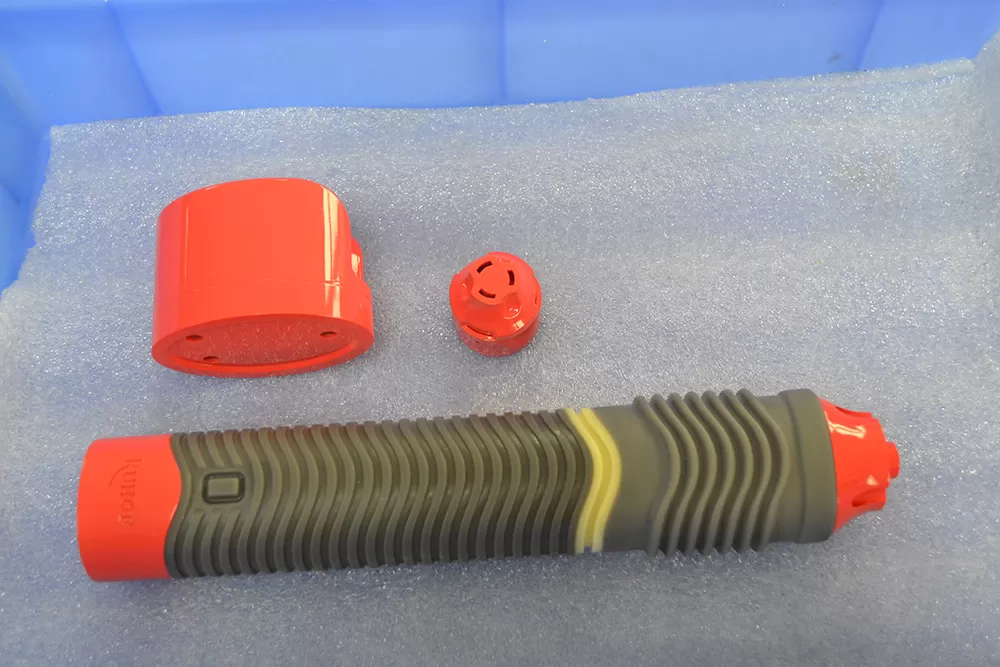

Processing method: vacuum molding

Material: ABS

Maximum precision: 0.05mm Production cycle: 2~3 days

Product size: 15cm*3cm*3cm

Post-processing: oil spraying

案例介绍

医用清洁剂的原型制作是一个涉及多个步骤和复杂技术的专业过程。以下是原型制作的一般过程:

Design stage: Detailed design is required based on the functional and appearance requirements of the medical cleaner. This stage usually requires the use of professional 3D design software to create a digital model of the product.

Prototyping: After the design is completed, a prototype of the product needs to be produced. This prototype is usually used to verify the feasibility of the design and as a reference for subsequent processing.

CNC machining: CNC (computer numerical control) machining is a common prototype manufacturing process that uses programmed instructions to control machine tools to accurately remove materials and produce parts with precise dimensions and complex shapes. CNC machining can process a variety of materials such as ABS, PC, PMMA, aluminum and copper, which have good toughness and strength.

Post-processing: After CNC processing is completed, manual post-processing is usually required, including polishing, painting, printing, etc., to ensure the surface quality and aesthetics of the prototype model.

Silicone duplication: If you need to make multiple sets of prototypes, you can use silicone duplication technology. This method uses the original sample to make a silicone mold, and then pours PU material under vacuum to make a replica that is identical to the original sample. This method is low-cost and suitable for small and medium-sized batch production.

Quality Control: Throughout the entire processing process, strict quality control is required to ensure that each link meets design requirements and industry standards.

Delivery to the customer: After completing all processing steps, the prototype model is delivered to the customer for final testing and verification.

在选择合适的供应商时,您可以考虑提供一站式服务的公司,例如HXC,它提供从设计到原型模型、数控加工等一系列全面的解决方案。

综上所述,医用清洁剂的原型制作是一个结合了现代设计和精密制造技术的复杂过程,需要专业团队和设备才能完成。通过这个过程,可以确保在实际生产之前对医用清洁剂的设计进行充分的验证和优化。