Пример обработки прототипа для автомобиля — рама фара

2025-04-14

Профессиональные и надёжные решения для двуцветных форм и инъекционного формования

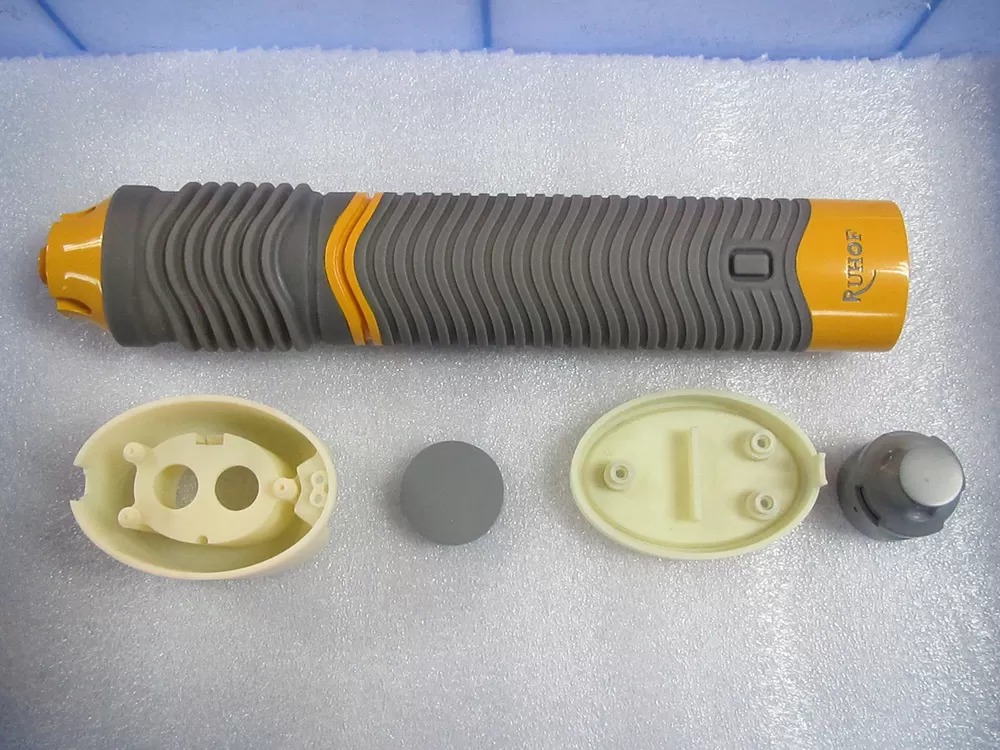

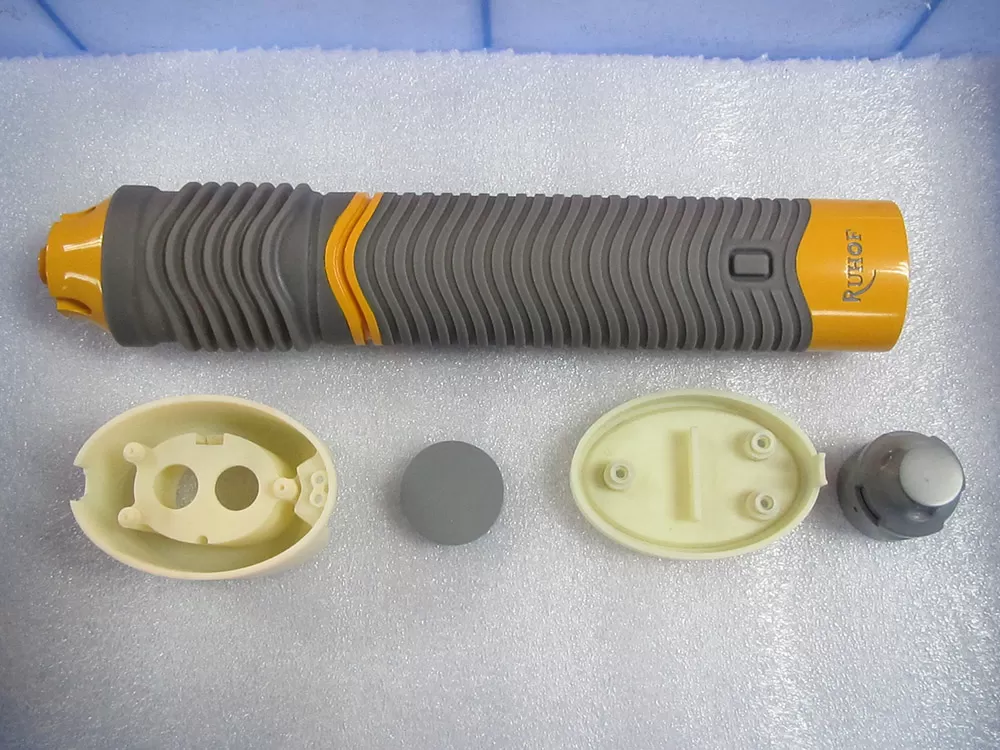

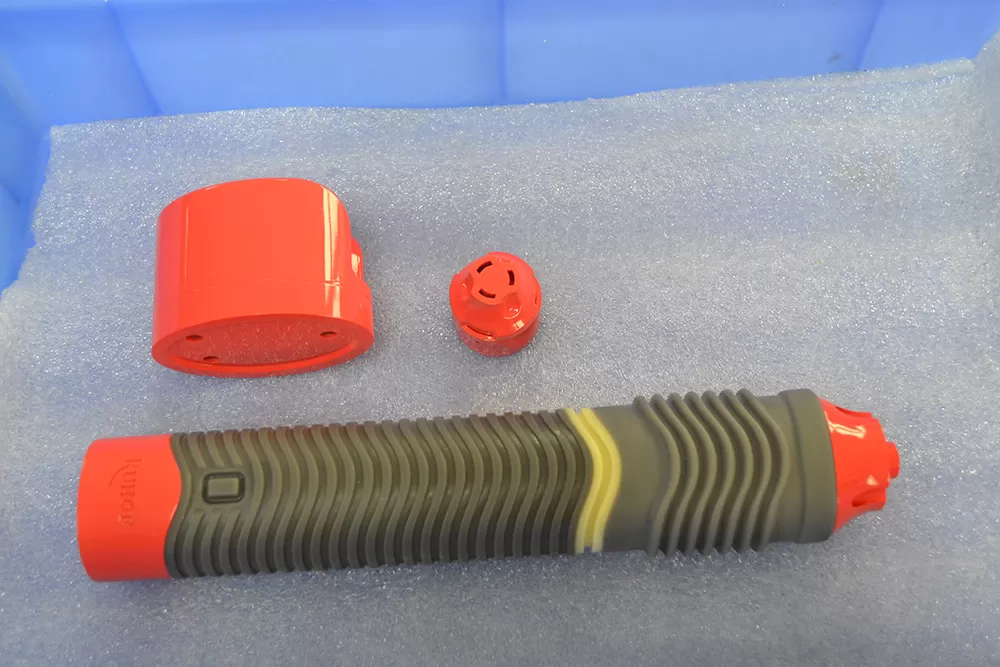

2025-04-16Прототипный случай - медицинский очиститель

Введение в пример

The prototyping of medical cleaners is a professional process involving multiple steps and sophisticated techniques. Here is the general process of prototyping:

Изготовление прототипа: После завершения дизайна требуется изготовить прототип продукта. Этот прототип обычно используется для проверки целесообразности дизайна и как ориентир для последующей обработки.

Обработка на ЧПУ: Обработка на ЧПУ (компьютерное числовое управление) — это распространенный процесс изготовления прототипов, который использует запрограммированные инструкции для управления станками с целью точного удаления материала и производства деталей с точными размерами и сложными формами. Обработка на ЧПУ может обрабатывать различные материалы, такие как ABS, PC, PMMA, алюминий и медь, обладающие хорошей прочностью и упругостью.

Постобработка: После завершения обработки на ЧПУ обычно требуется ручная постобработка, включая полировку, покраску, печать и т.д., чтобы обеспечить качество поверхности и эстетику прототипной модели.

Литье по силиконовой форме: Если необходимо изготовить несколько наборов прототипов, можно использовать технологию силиконового литья. Этот метод использует оригинальный образец для изготовления силиконовой формы, а затем разливает материал ПУ в вакууме, чтобы создать копию, идентичную оригинальному образцу. Этот метод имеет низкую стоимость и подходит для мелких и средних серийного производства.

Доставка клиенту: После выполнения всех этапов обработки прототипная модель доставляется клиенту для окончательных испытаний и проверки.

При выборе подходящего поставщика можно рассмотреть компании, предлагающие one-stop-сервисы, например, HXC, которая предоставляет целый комплекс решений от проектирования до изготовления прототипов, ЧПУ-обработки и т.д.

Создание прототипов медицинских очистителей - это сложный процесс, сочетающий современные технологии проектирования и точного производства. Для его реализации необходимы профессиональная команда и специализированное оборудование. Данный процесс позволяет провести полную проверку и оптимизацию конструкции медицинского очистителя до начала серийного производства.