自動車プロトタイプ加工事例 – ヘッドライトフレーム

2025-04-14

専門的かつ信頼性の高い二色金型及び射出成形ソリューション

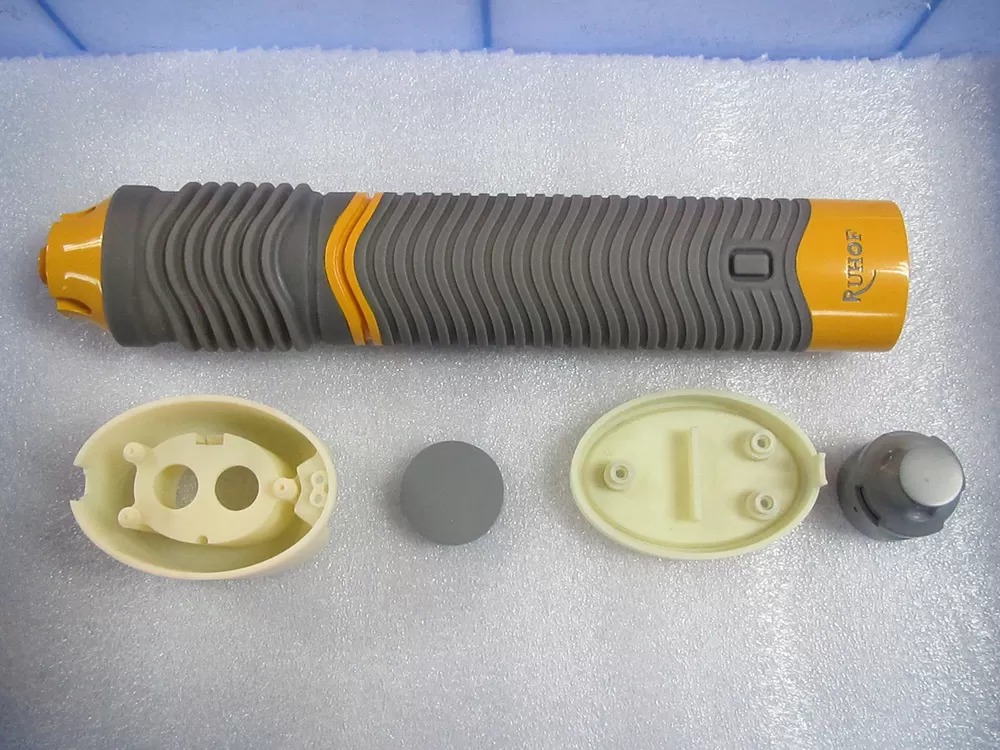

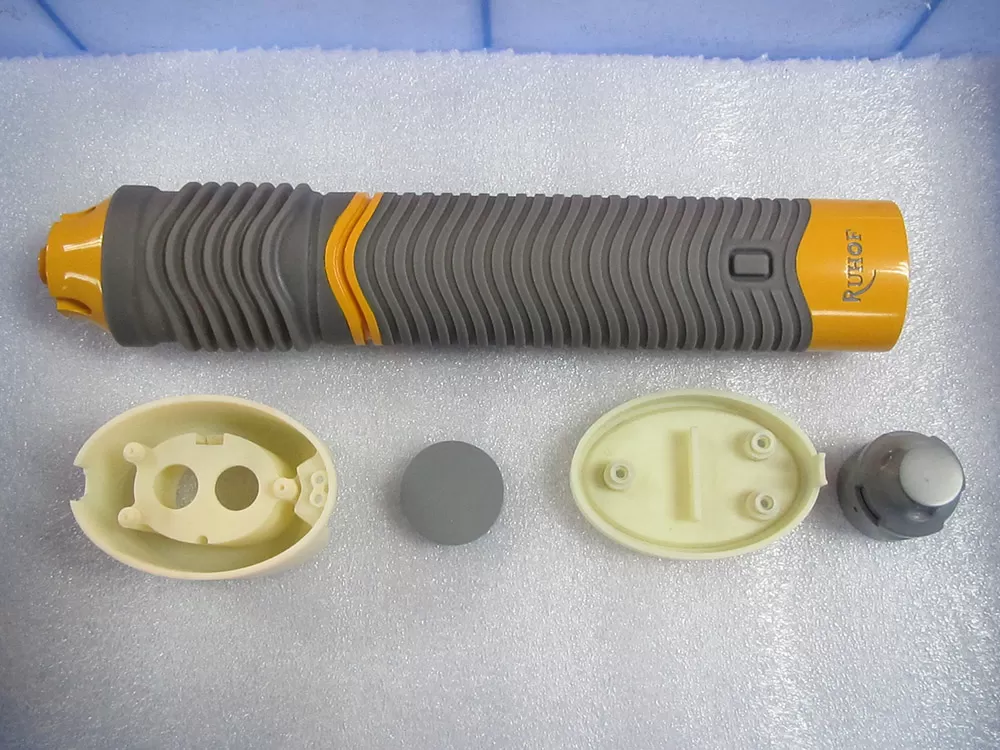

2025-04-16プロトタイプ事例-医療用クリーナー

加工方法:真空成形

材料:ABS樹脂

最高精度:0.05mm

生産サイクル:2~3日

製品サイズ:15cm×3cm×3cm

後処理:塗装(スプレー)

ケース紹介

医療用クリーナーのプロトタイピングは、複数の工程と高度な技術を組み合わせたプロフェッショナルなプロセスです。以下に、プロトタイピングの一般的な流れを示します:

設計段階:医療用クリーナーの機能的および外観上の要件に基づいて、詳細設計が必要です。この段階では通常、専門的な 3D 設計ソフトウェアを使用して製品のデジタルモデルを作成する必要があります。

プロトタイピング:設計が完了した後、製品のプロトタイプを製造する必要があります。このプロトタイプは通常、設計の実現可能性を検証するために使用され、後続の加工の参考とされます。

CNC 加工:CNC(コンピュータ数値制御)加工は一般的なプロトタイプ製造プロセスであり、プログラムされた命令を使用して工作機械を制御し、材料を正確に除去し、精密な寸法と複雑な形状を持つ部品を製造します。CNC 加工は、ABS、PC、PMMA、アルミニウム、銅など、良好な靭性と強度を備えたさまざまな材料を加工することができます。

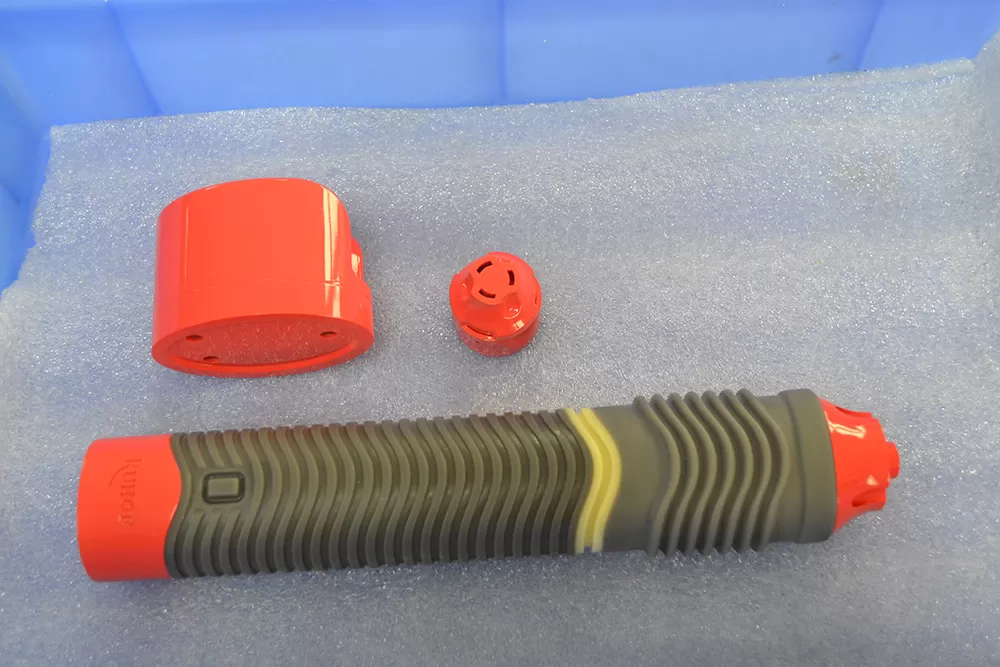

後処理:CNC 加工が完了した後、通常は手作業による後処理が必要です。これには研磨、塗装、印刷などが含まれ、プロトタイプモデルの表面品質と美観を確保します。

シリコン複製:複数セットのプロトタイプが必要な場合、シリコン複製技術を利用できます。この方法ではオリジナルサンプルを使用してシリコンモールドを作成し、真空下でPU材を注入することで、オリジナルと同一の複製品を製作します。コストが低く抑えられ、中小ロット生産に適しています。

品質管理:加工プロセス全体において、設計要求や業界基準を満たすため、各工程で厳格な品質管理を実施する必要があります。

お客様への納品:全ての加工工程を完了後、プロトタイプモデルを最終テストと検証のために顧客へ引き渡します。

適切なサプライヤーを選定する際には、HXCのようなワンストップサービスを提供する企業を検討できます。HXCは設計から試作モデル、CNC加工まで一連の包括的なソリューションを提供しています。

要約すると、医療用クリーナーのプロトタイピングは、現代的なデザインと精密製造技術を融合した複雑なプロセスであり、専門チームと設備が必要となります。このプロセスを通じて、医療用クリーナーの設計が本格的な生産前に完全に検証・最適化されることを確保することができます。