Cas d’utilisation de prototypage automobile – Cadre de phare

2025-04-14

Solutions professionnelles et fiables pour les moules bicouleurs et le moulage par injection

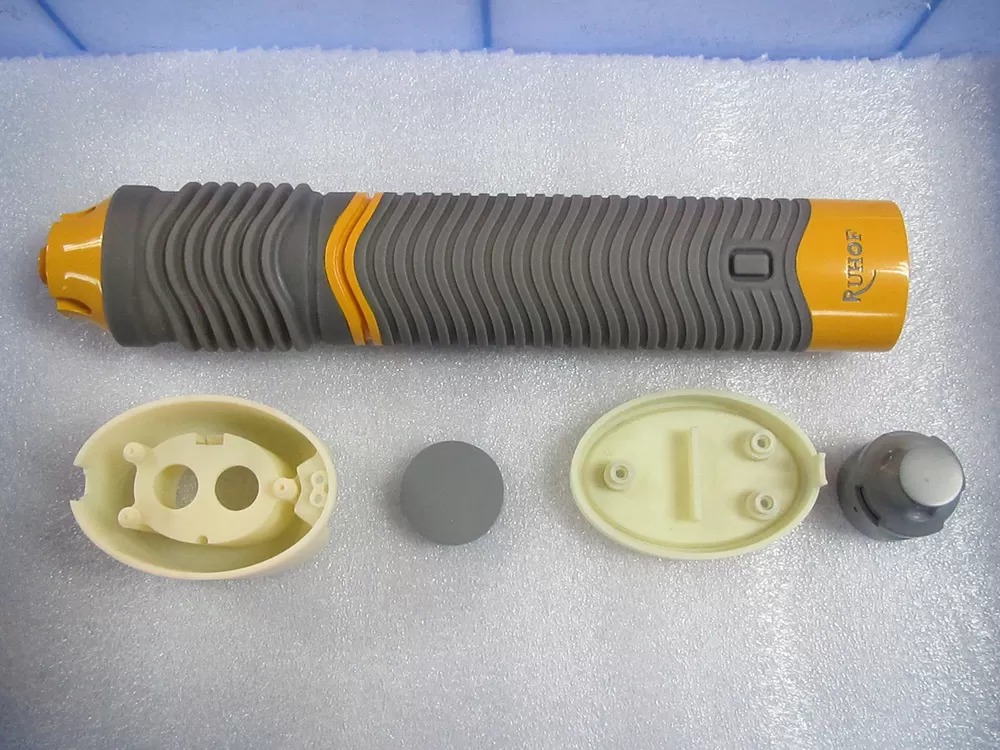

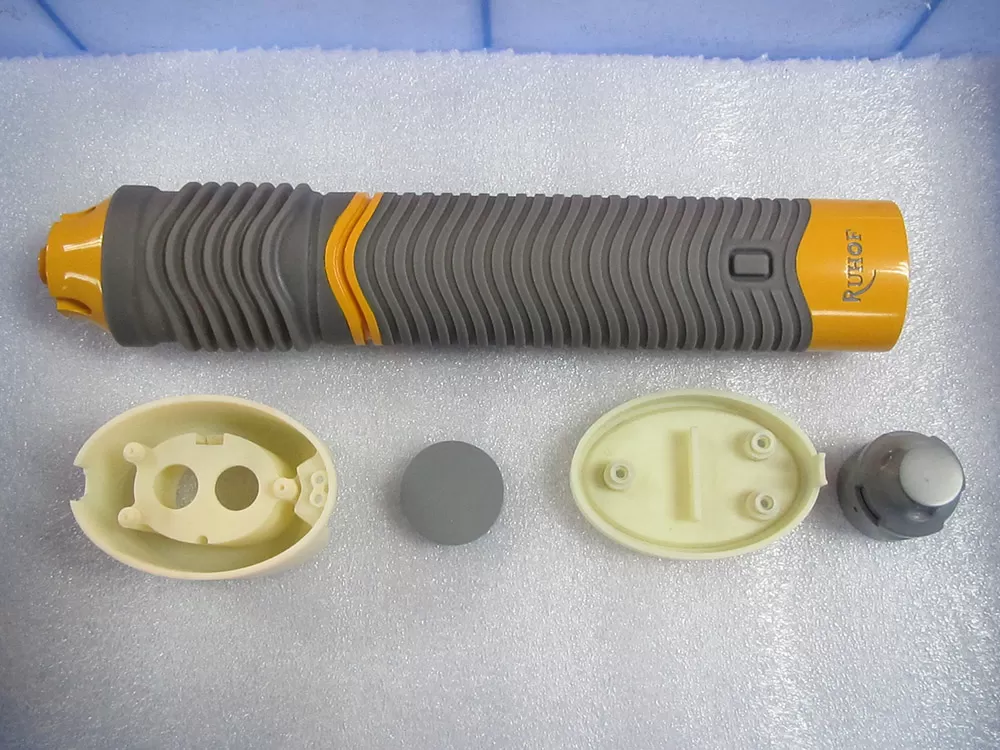

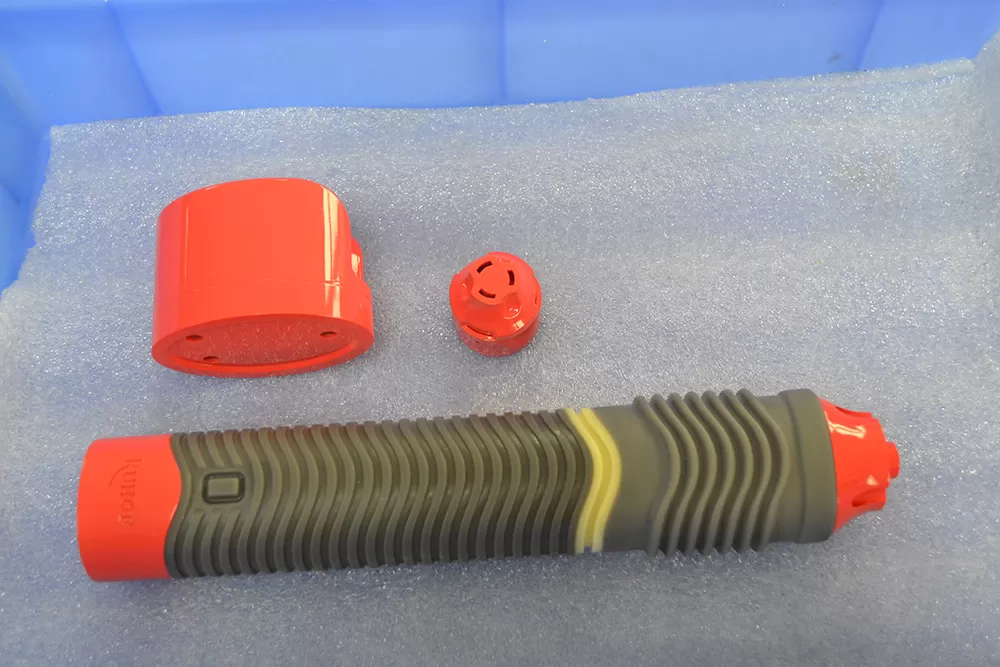

2025-04-16Cas de prototype : Nettoyeur médical

Méthode de traitement : Moulage sous vide

Matériau : ABS

Précision maximale : 0,05 mm

Cycle de production : 2~3 jours

Taille du produit : 15 cm × 3 cm × 3 cm

Post-traitement : Pulvérisation d'huile

Présentation du cas

Le prototypage des nettoyeurs médicaux est un processus professionnel impliquant plusieurs étapes et des techniques sophistiquées. Voici le processus général de prototypage :

Étape de conception : Un design détaillé est nécessaire selon les exigences fonctionnelles et esthétiques du nettoyeur médical. Cette phase requiert généralement l'utilisation de logiciels professionnels de CAO 3D pour créer un modèle numérique du produit."

Prototypage : Une fois le design finalisé, un prototype du produit doit être réalisé. Ce prototype sert généralement à valider la faisabilité de la conception et constitue une référence pour les procédés ultérieurs."

Usinage CNC : L'usinage à commande numérique (CNC) est un procédé courant de fabrication de prototypes qui utilise des instructions programmées pour contrôler des machines-outils afin d'éliminer avec précision la matière et produire des pièces aux dimensions exactes et aux formes complexes. L'usinage CNC peut traiter divers matériaux tels que l'ABS, le PC, le PMMA, l'aluminium et le cuivre, qui possèdent une bonne résilience et résistance."

Post-traitement : Après l'usinage CNC, un post-traitement manuel est généralement nécessaire comprenant le polissage, la peinture et l'impression, afin d'assurer la qualité de surface et l'esthétique du prototype."

Duplication en silicone : Pour produire plusieurs séries de prototypes, la technique de moulage silicone peut être utilisée. Cette méthode consiste à créer un moule en silicone à partir de l'échantillon original, puis à couler du matériau PU sous vide pour obtenir des répliques identiques à l'original. Cette solution économique est adaptée à la production en petites et moyennes séries."

Contrôle qualité : Un contrôle qualité rigoureux est nécessaire tout au long du processus de fabrication pour garantir que chaque étape respecte les exigences de conception et les normes industrielles.

Delivery to the customer: After completing all processing steps, the prototype model is delivered to the customer for final testing and verification.

Pour choisir un fournisseur adapté, privilégiez les entreprises offrant des services clés en main comme HXC, qui propose des solutions complètes couvrant toute la chaîne de conception, de prototypage jusqu'à l'usinage CNC."

En résumé, le prototypage des nettoyeurs médicaux est un processus complexe qui combine la conception moderne et la technologie de fabrication de précision, et nécessite une équipe et du matériel professionnels pour être achevé. Grâce à ce processus, on peut s'assurer que la conception du nettoyeur médical est entièrement vérifiée et optimisée avant la production réelle.